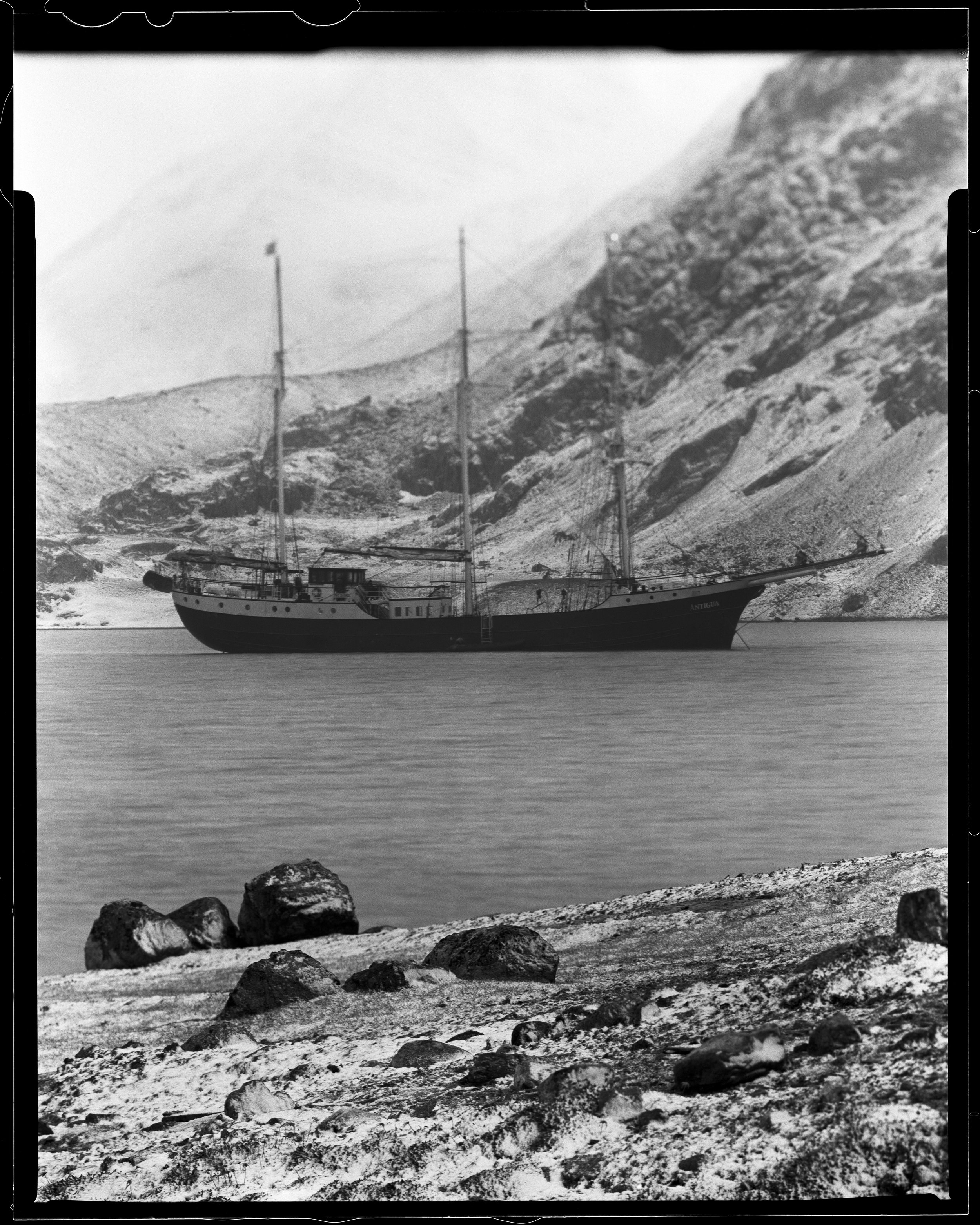

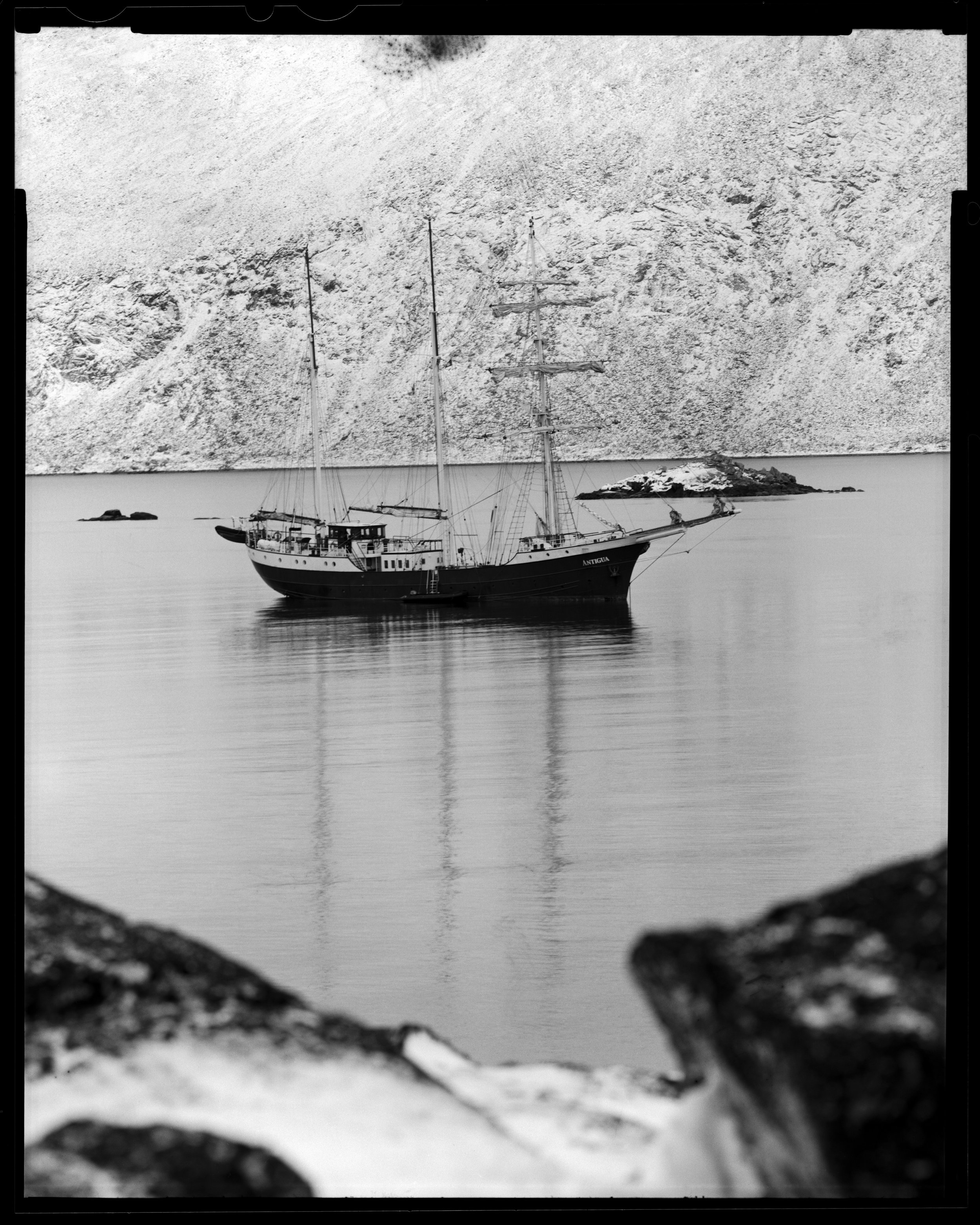

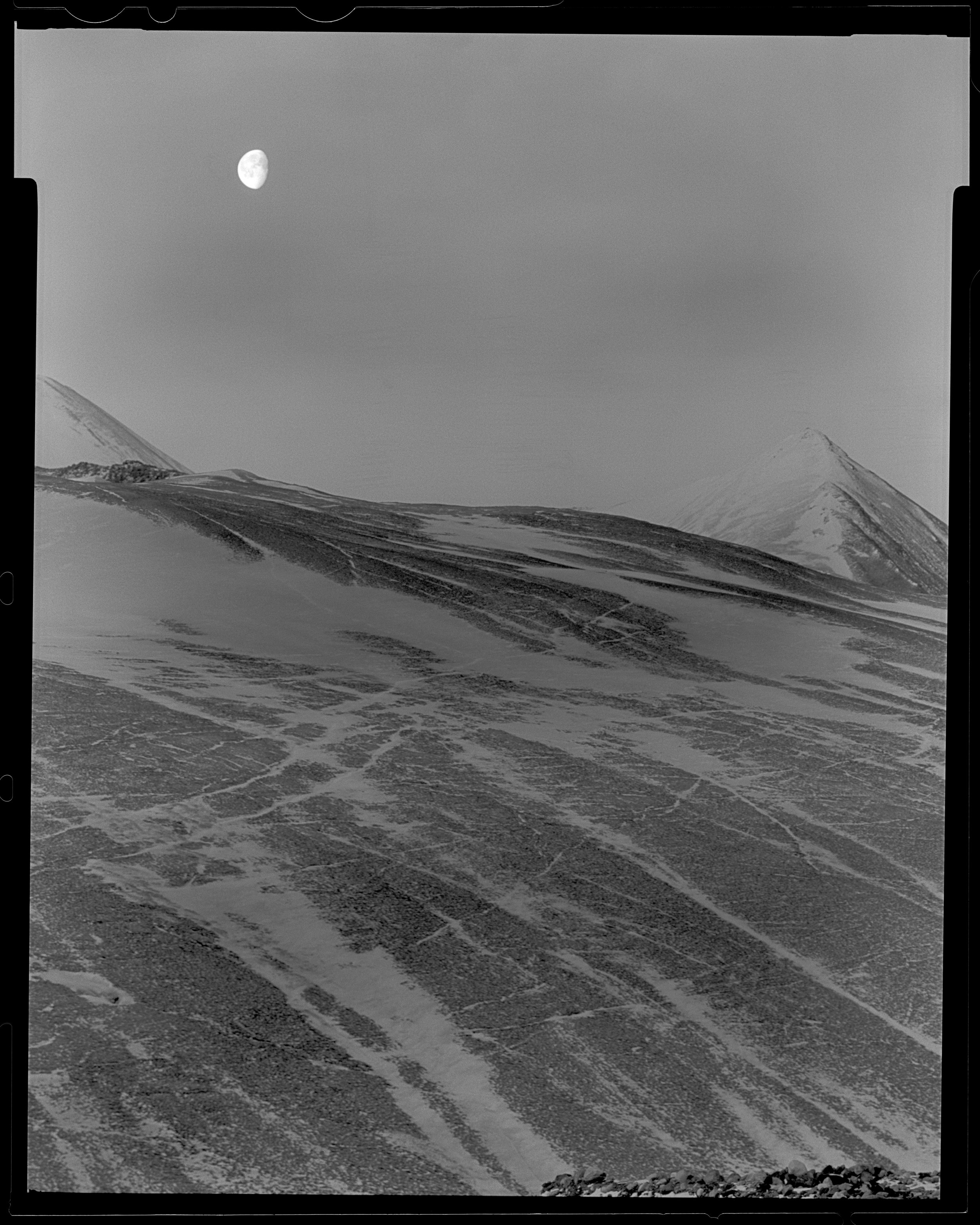

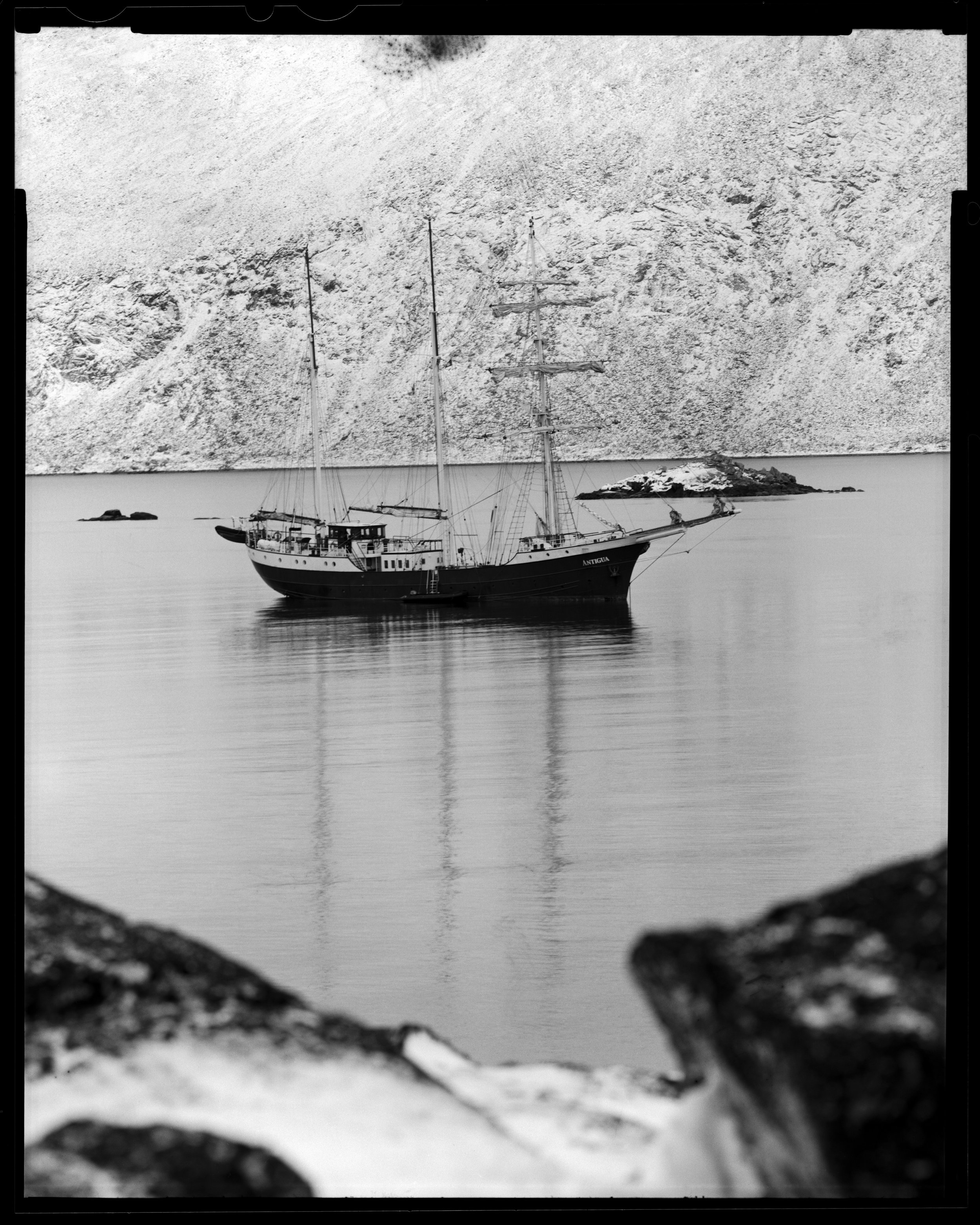

While visiting a historic miners’ cabin in Gipsdalen valley in Sassenfjorden, Spitsbergen, I captured this view of our ship, Antigua, at single anchor in Gipsvika Bay. It was mid-October and the stream cutting through the glacial moraine in the foreground was frozen solid. Svalbard has no trees and little soil and a dusting of new snow highlights the layers of ancient sedimentary rock forming its mountains.

This sheet film was developed onboard our tall ship as we sailed.

While visiting a historic miners’ cabin in Gipsdalen valley in Sassenfjorden, Spitsbergen, I captured this view of our ship, Antigua, at single anchor in Gipsvika Bay. It was mid-October and the stream cutting through the glacial moraine in the foreground was frozen solid. Svalbard has no trees and little soil and a dusting of new snow highlights the layers of ancient sedimentary rock forming its mountains.

This sheet film was developed onboard our tall ship as we sailed.

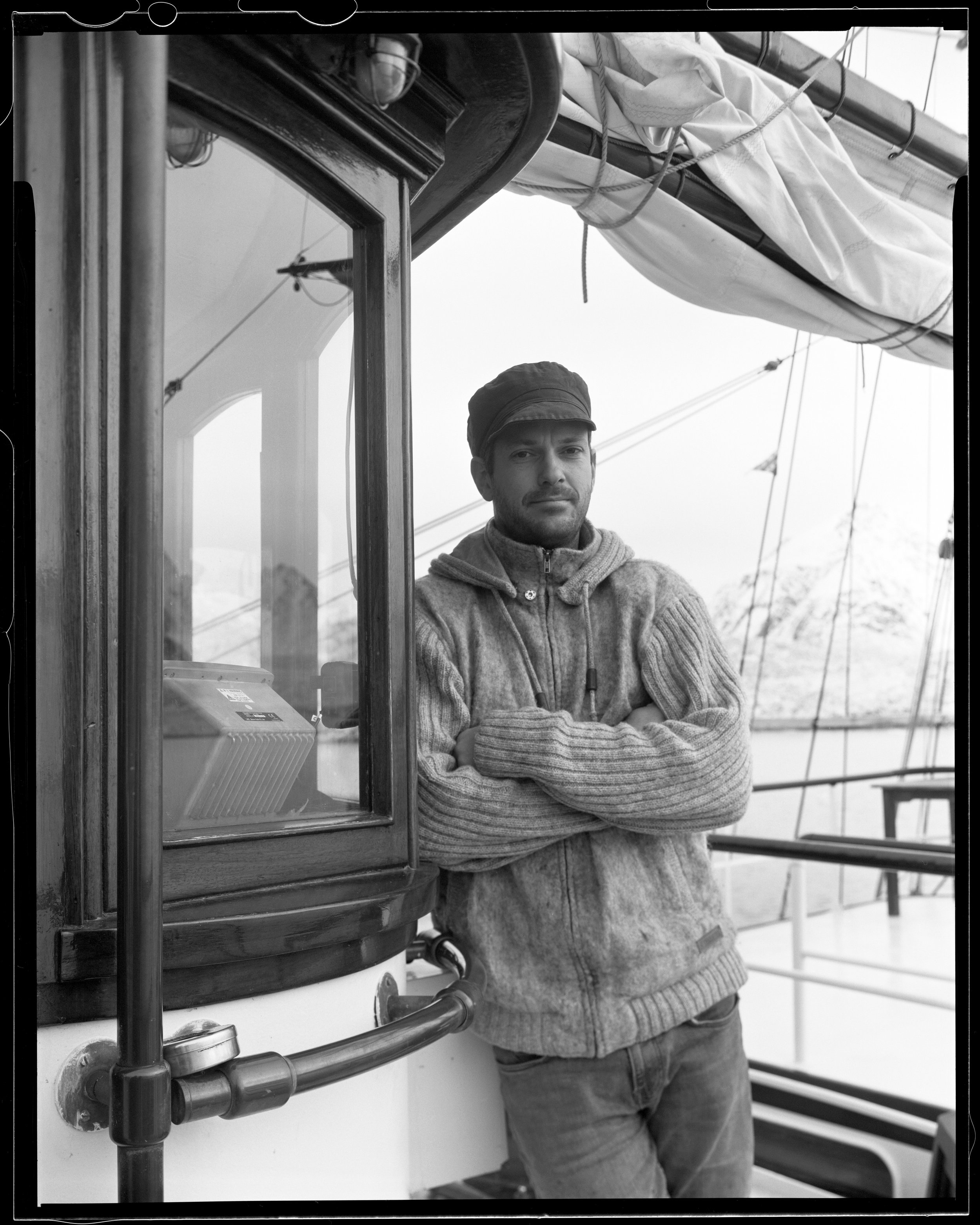

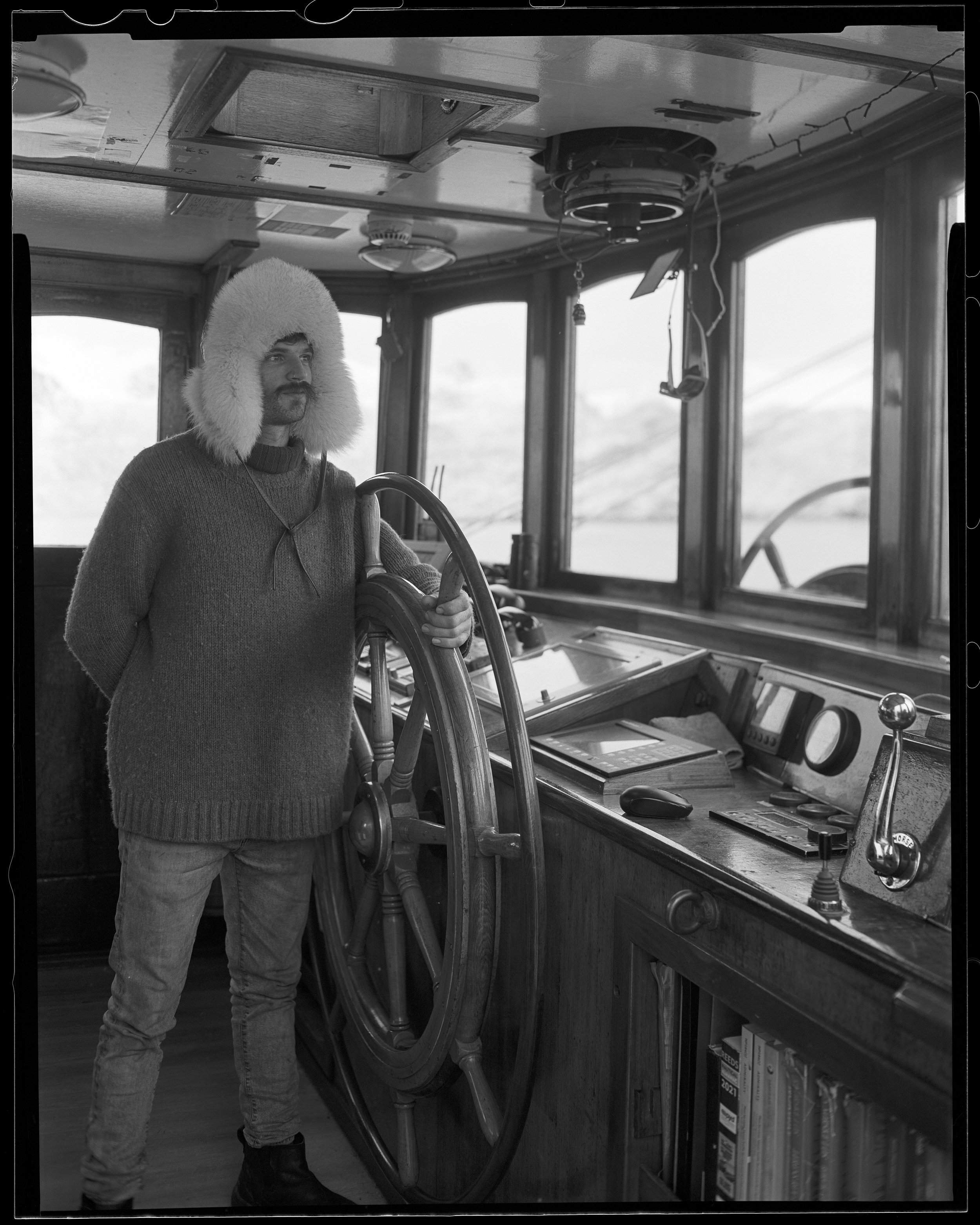

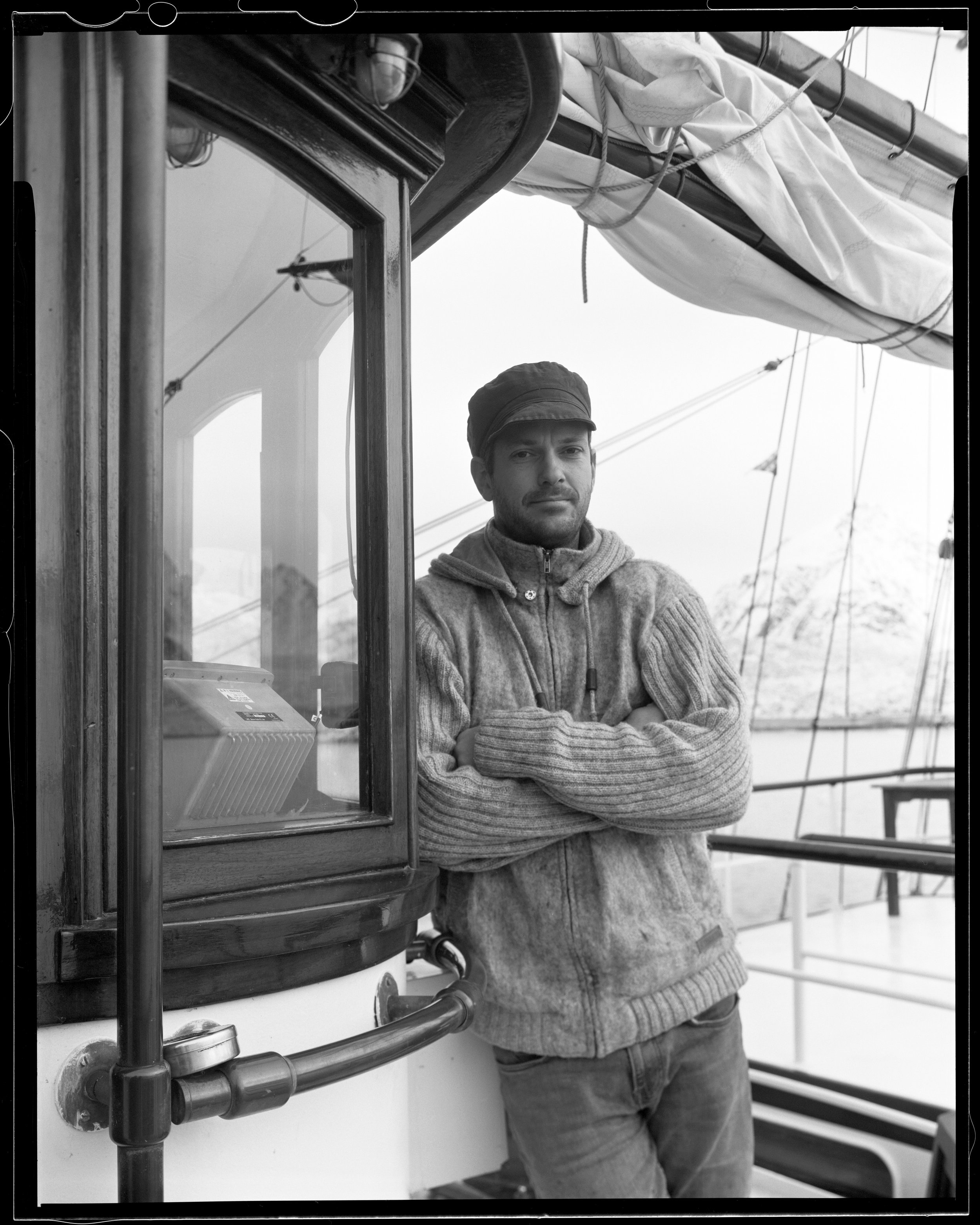

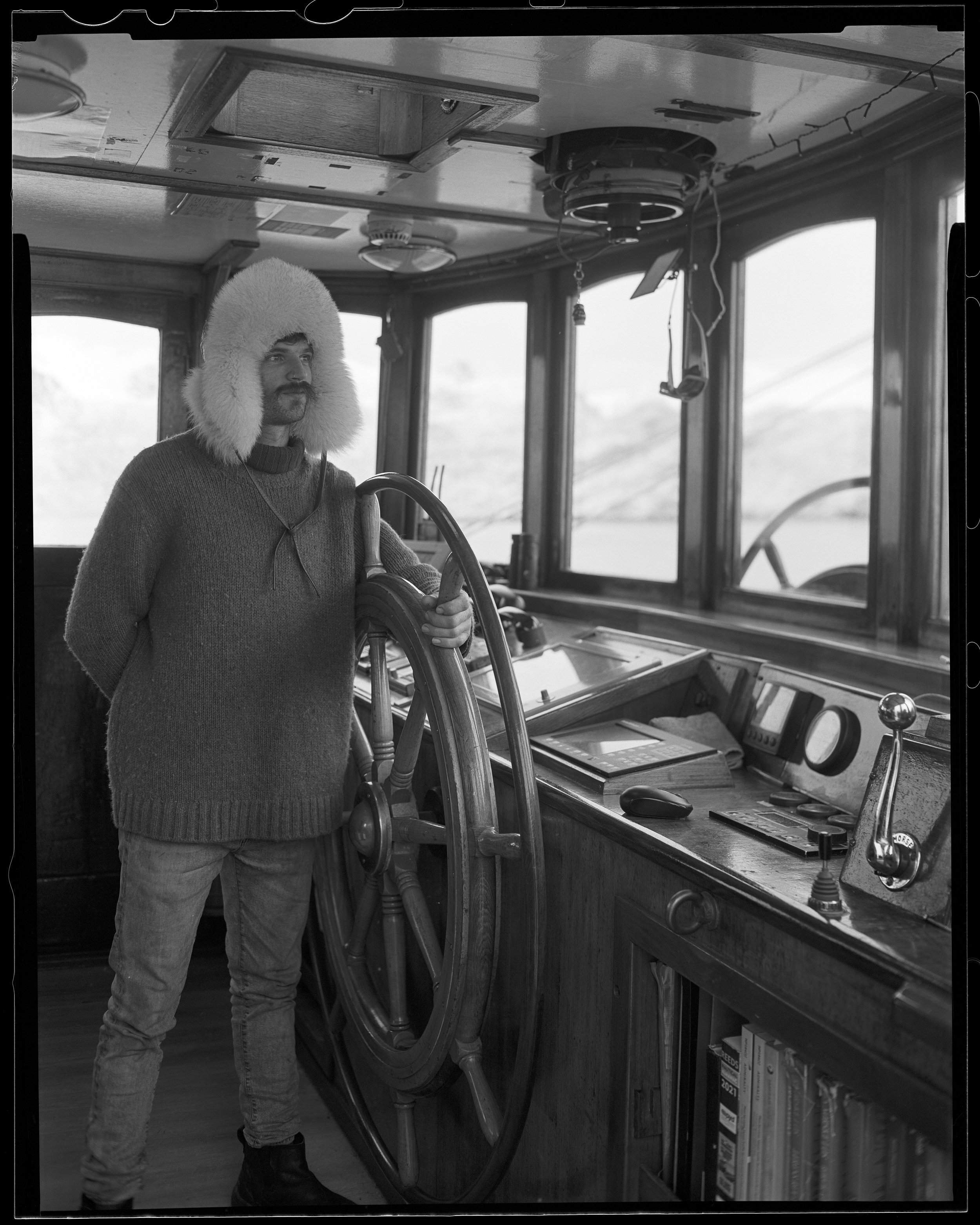

Captain of the tall ship Antigua, Jonathan, outside the wheelhouse. We sailed under wind power more on this voyage than the ship had on all others combined this season.

The Antigua is rigged as a barquentine, three masts with square sails on the foremast only, fore-and-aft rigged on the main and mizzen. It only takes a small crew to operate, although passengers like myself were welcomed to haul lines, set sheets, and furl sails with the crew.

I was making a portrait of the first mate, Matu, inside the wheelhouse. Jonathan was sitting back, watching us, making the occasional comment for Matu and smirking a bit. Then Matu had to leave to deal with something.

I was putting stuff away when Jonathan asked what it was all about. I said I thought it might be fun to get some photos of the people who brought us out here. I said I’d be happy to make a picture of him if he wanted. He said, “No, I don’t need to.”

To which I replied, “Yeah, no worries! I don’t need to bother everybody.”

“Well . . . I could do one.”

“Ok, sure. Let me set up something a little different. Maybe out here…?”

I made two shots in this absolutely beautiful light in front of the wheelhouse and they both turned out.

At the end of this season, Jonathan is giving up captaincy to head back to the Netherlands to be a kindergarten teacher (for which sailing a bunch of us around the dangers of the Arctic might well prepare him).

This sheet film was developed onboard our tall ship as we sailed.

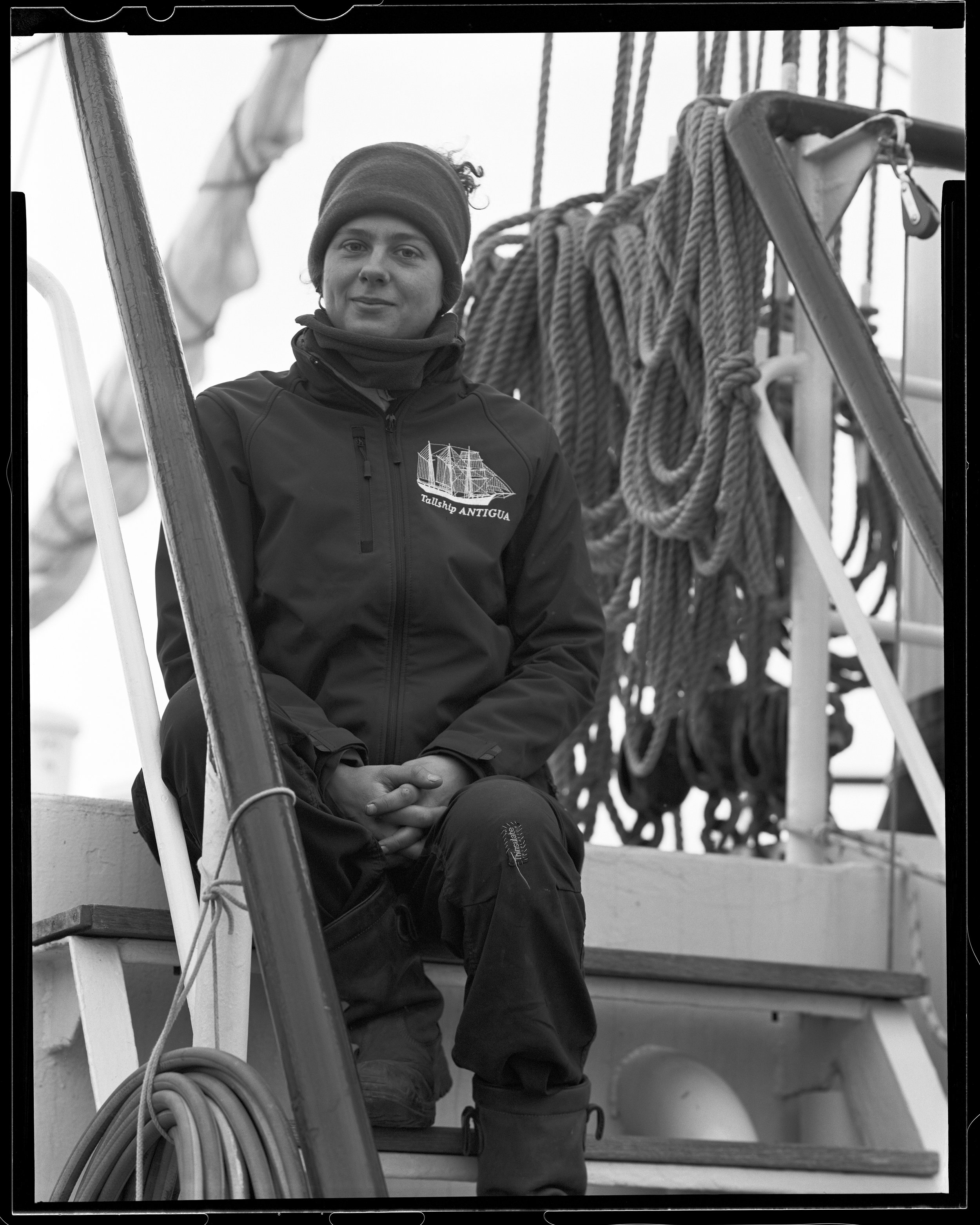

Our expedition manager and lead guide, Sarah. This was taken in Virgohamna on Danskøya, the launch site for Andrée’s ill-fated balloon attempt for the North Pole in 1897. The site is still littered with wood from structures and metal barrel hoops, all protected and untouchable. In fact, we couldn’t venture as far as we would like because a fresh dusting of snow made it impossible to know what we might be stepping on so we stayed strictly along the high water mark of the shore.

Note, Sarah’s rifle. It is illegal to be on land without rifles and flares (and training) as protection from polar bears. The goal is never to kill a bear except as a last resort. Both gun and flare are used to scare off a bear while humans find a way to retreat.

The guides would visit a landing first, then if everything was safe and land-able, the artists would come over about 8 or 10 at a time in a zodiac. The ship had three zodiacs but we typically only used the two larger ones. The guides would set up a perimeter in which we could work. They kept watch on the surroundings. Only twice did we ever see polar bears in the distance. Notice Sarah’s radio near her collar. The guides and the ship kept in close communication the whole time we were out.

Since we had such good winds, we sailed to far off places we had no right to expect to visit. Some of our crew and guides had seen a few of these sites before but we quickly got the sense that we were really exploring, not checking off a list, and our plans changed with the weather.

This sheet film was developed onboard our tall ship.

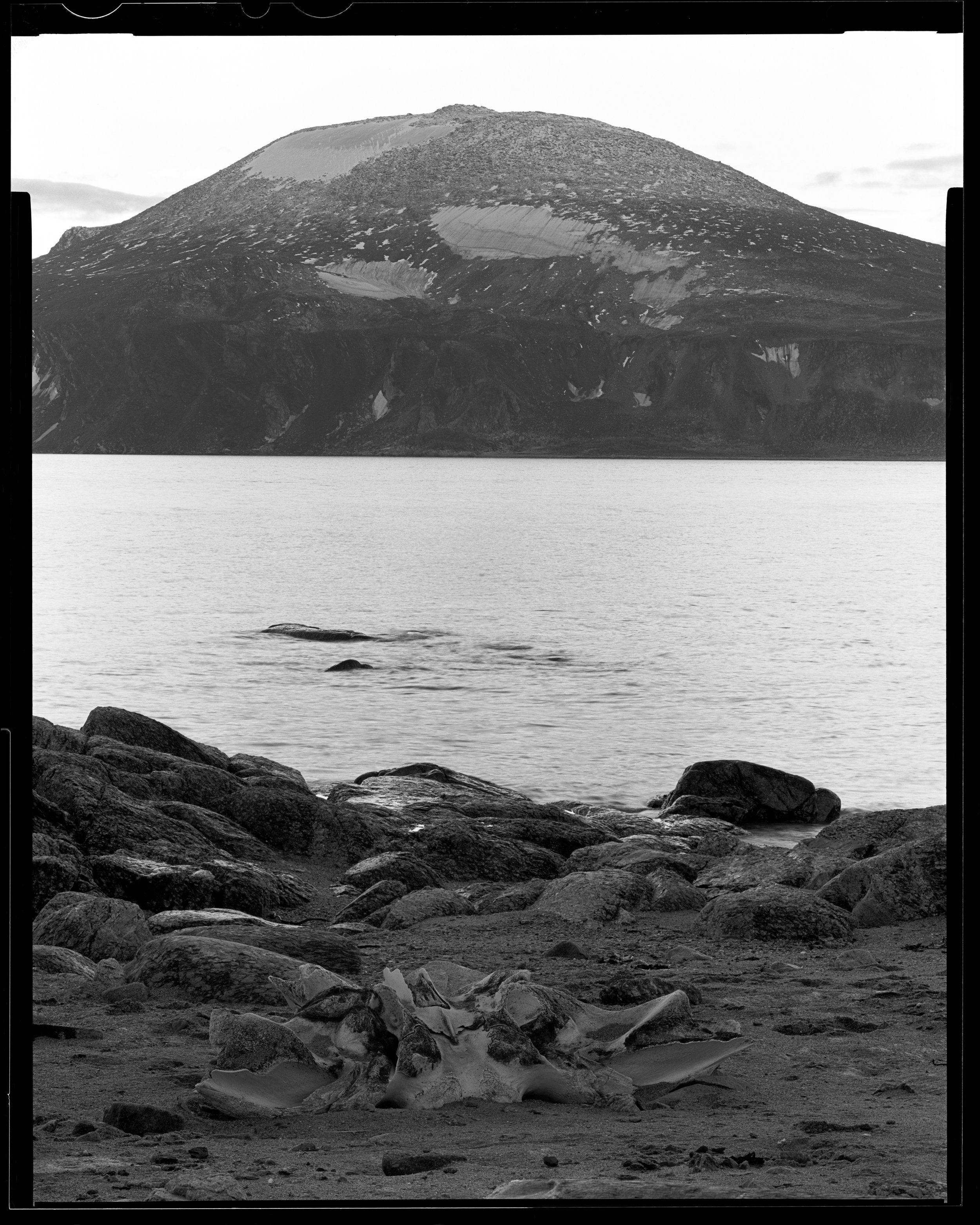

Sailing the Antigua into Hornbækpollen through a small break in the rocks that form this tiny bay was damned exhilarating! We were under wind power alone. I helped work the foremast square sails from the forepeak.

We had to furl sails to slow down but the wind in the rigging kept us moving at a couple knots. We slipped through a gap that was a biscuit toss to either side with little more than a meter or two under our keel. Once through, we had to work smartly lest we run aground. We brought the yards around, started our turn, dropped anchor, and, as we drifted over, came to the sweetest stop. Cheers and high fives all around!

Once all was ship shape, we dropped a zodiac and motored back to those rocks to catch the last light of the day. Clouds and fog rolled in and it began to snow.

The shot looks bright but I could hardly see the image on the ground glass. It was getting cold and my breath fogged the camera, my glasses, and the loupe. I used several degrees of tilt to put the plane of focus through the foreground, ship’s hull, and distant mountains. Because of the low light and the movement of the ship, I couldn’t stop down much. Those masts fall out of focus pretty quickly but I really like the final image.

The next day, we would climb that ridge in the background to see what was on the other side.

This sheet film was developed aboard our tall ship as we sailed.

Here we were anchored at Sallyhamna in Fairhaven in the far northwest of Spitsbergen. We had tremendously favorable winds that swept us up the west coast overnight.

The cabin belonged to Waldermar and Sally Kraemer (after whom the harbor is named). It was built in 1937 over an older whaler’s blubber oven. Other blubber ovens dot the landscape to the right. Sally wintered-over here alone.

This was one of the few sites we visited with a healthy growth of moss and lichen. This is because century-old oils and blood from whales still provide enough organic nutrients to support their growth. These lichens are protected, as are the remnants of structures. People are not allowed to walk on them.

This sheet film was developed onboard our tall ship as we sailed.

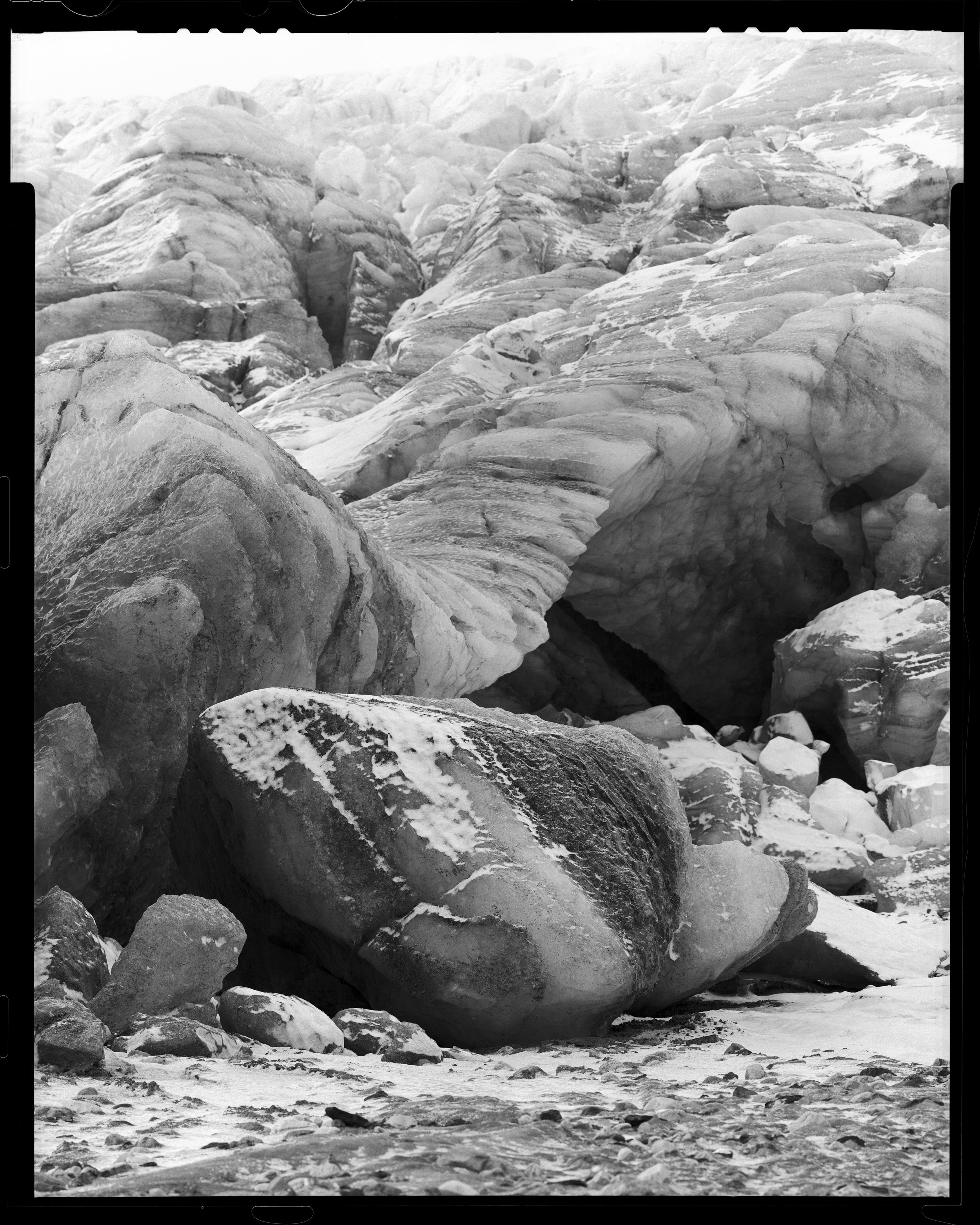

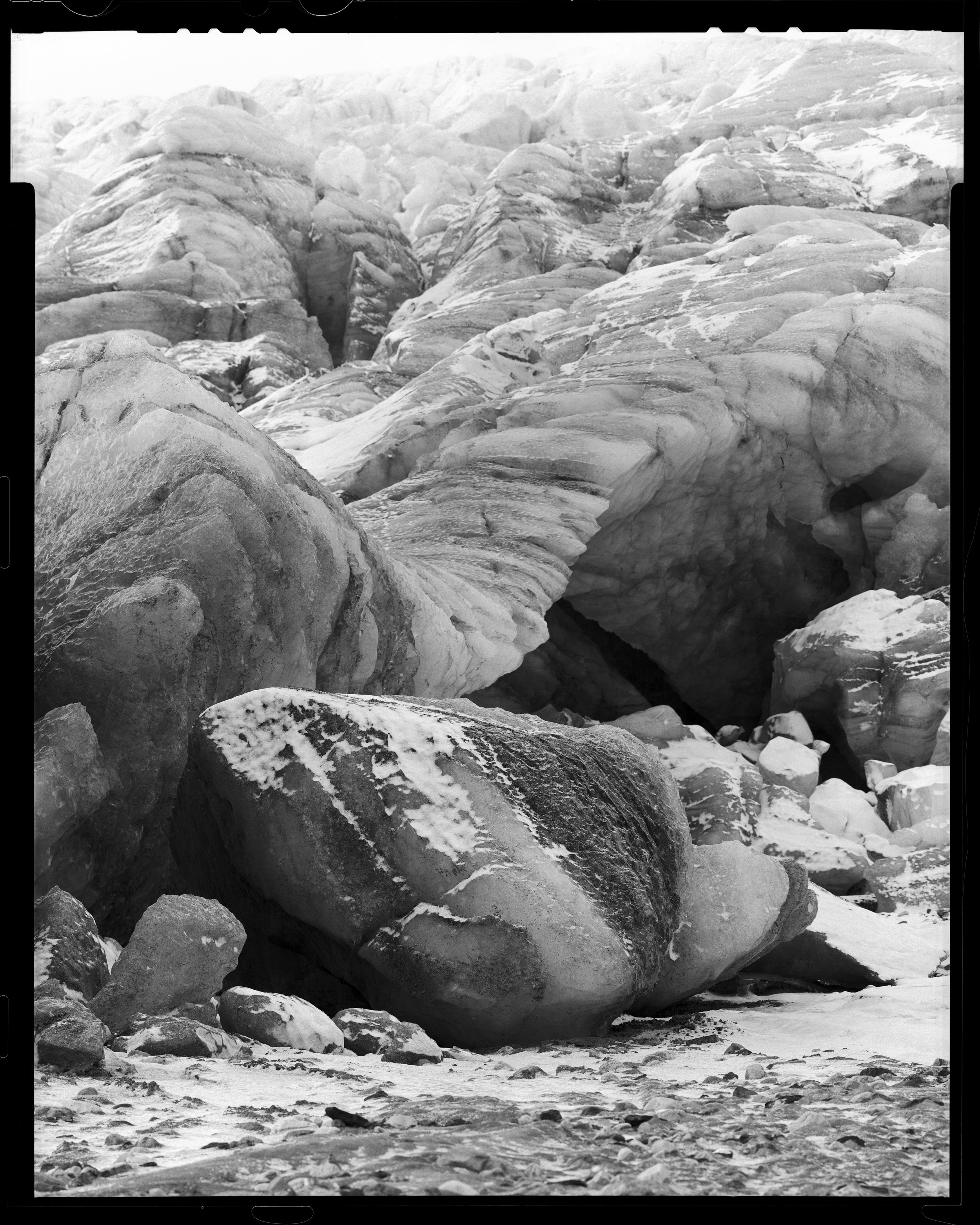

Esmarkbreen was one of the few glaciers we could walk up to. This spectacularly twisted ice form leaned perilously over but, so far, has refused to succumb to gravity. The moraine I am standing on was covered by several stories worth of glacial ice a decade earlier.

Ymerbukta Bay was near the end of our time onboard. In Norse mythology, Ymer was the first being and father of giants. When he was slain, Odin used his body to create the earth, water, and sky.

To stand dwarfed at the foot of an ancient glacier is to experience those primordial beginnings of our world. Some glaciers are alive with grinding, crashing, even thundering noise and it can be difficult to tell exactly where the sound is coming from. Some calve dramatically into the sea. Esmarkbreen was quieter than others and invited us to come close, which made it all the more impressive.

We had several hours to work on the moraine on this particularly cold afternoon. Days were getting shorter by nearly twenty minutes per day and the moon was up pretty much all hours. As we worked, the sky dimmed, the moon got brighter, and cold air washed down on us from above.

Despite the chill in the air, Svalbard is warming six times faster than the rest of the world. This problem will accelerate as thawing permafrost releases methane, over twenty times more effective than carbon dioxide as a greenhouse gas. Dark surfaces like the moraine absorb heat. Glacier shrinkage and loss of pack ice also reduces the earth’s capacity to reflect solar gain back out of the atmosphere.

The ice in this photo is thousands, if not tens of thousands, of years old. In the past hundred years, Esmarkbreen has retreated five kilometers or about a quarter of its length. How long does Esmarkbreen have before it succumbs entirely?

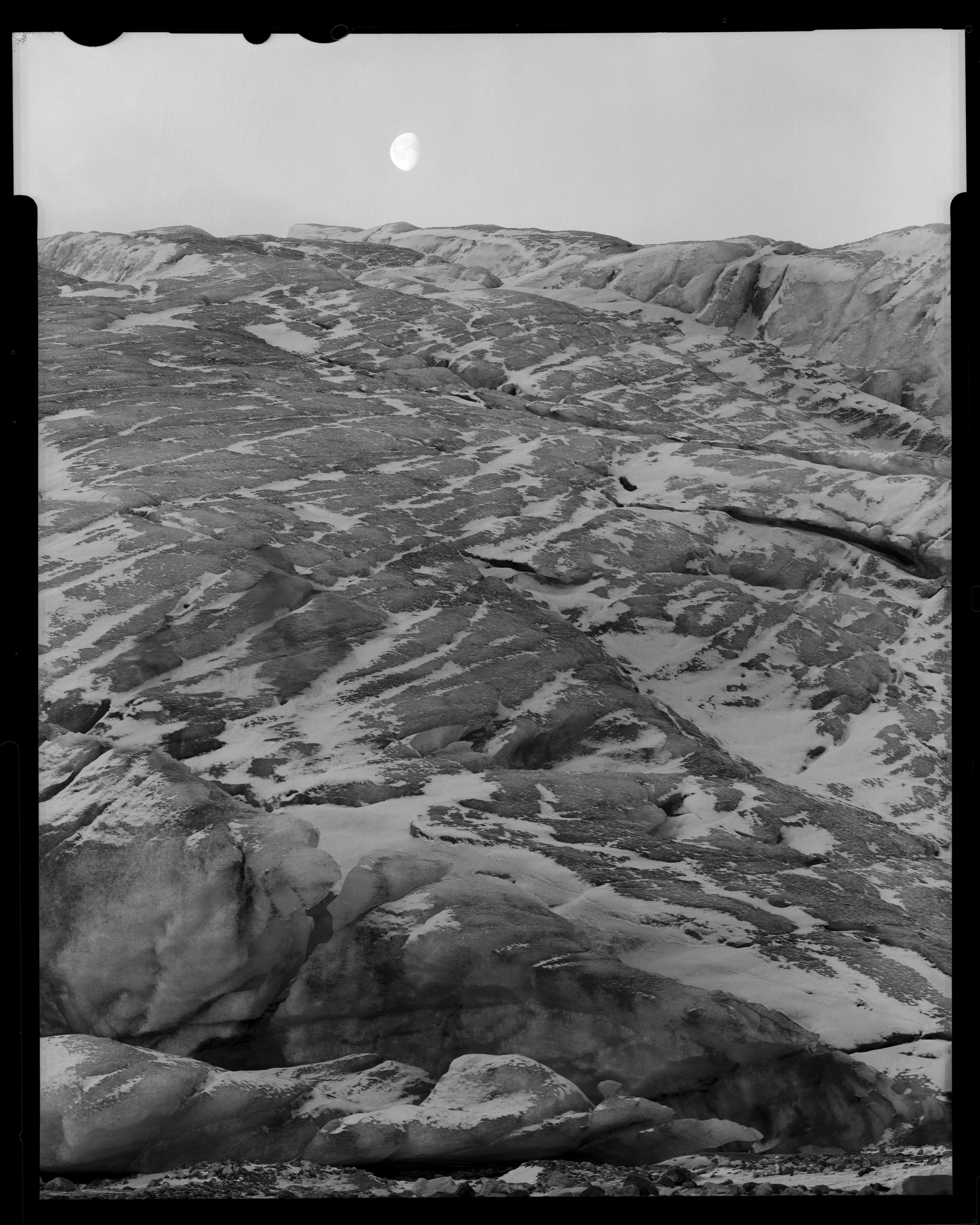

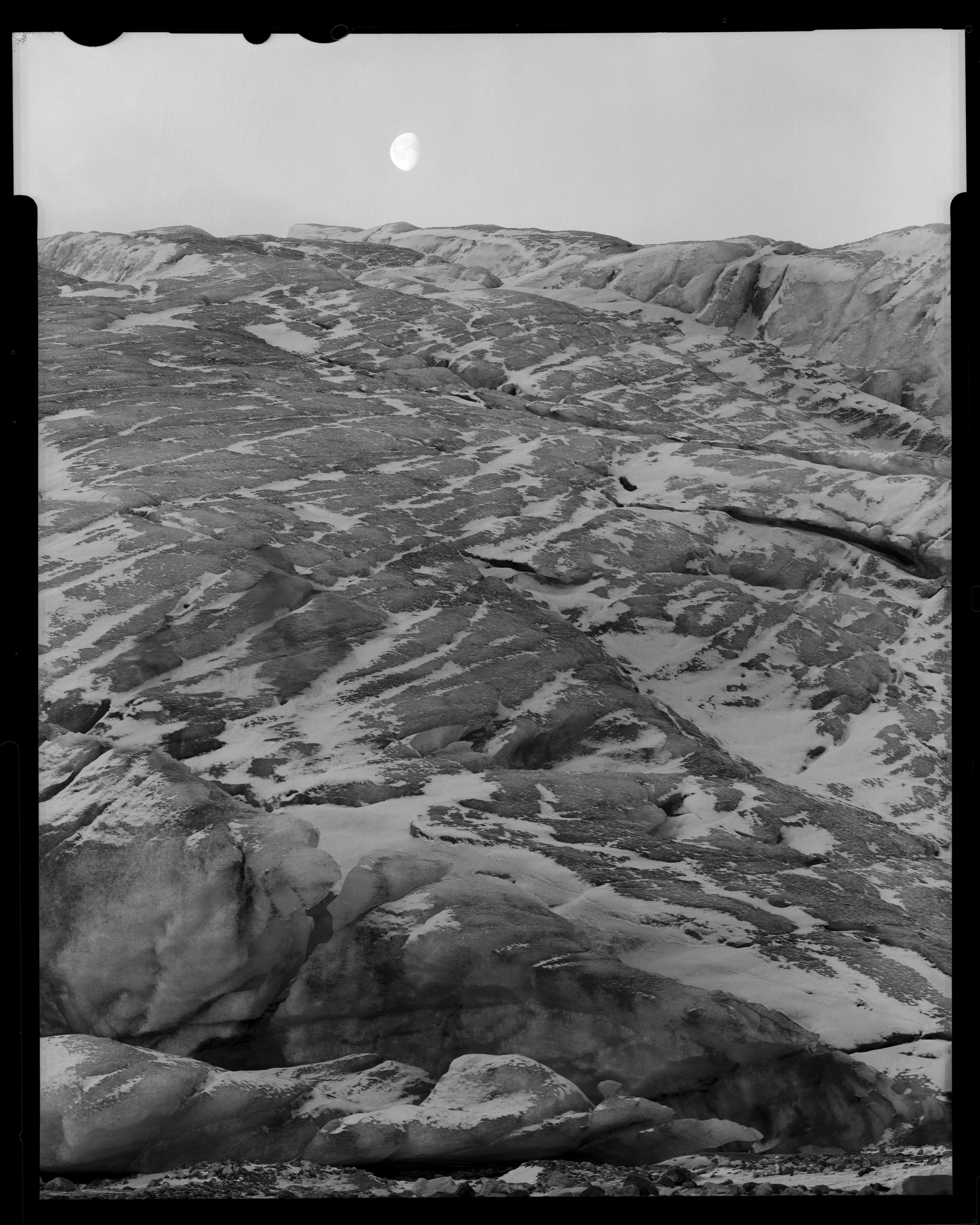

Some days the light was so strange and wonderful. Every day had about twenty minutes less daylight than the one before it. Sometimes the sun and the moon would hang above opposite sides of the horizon.

This moonrise was toward the end of our trip at Esmarkbreen Glacier. As light quickly faded in the afternoon, the full moon grew more distinct.

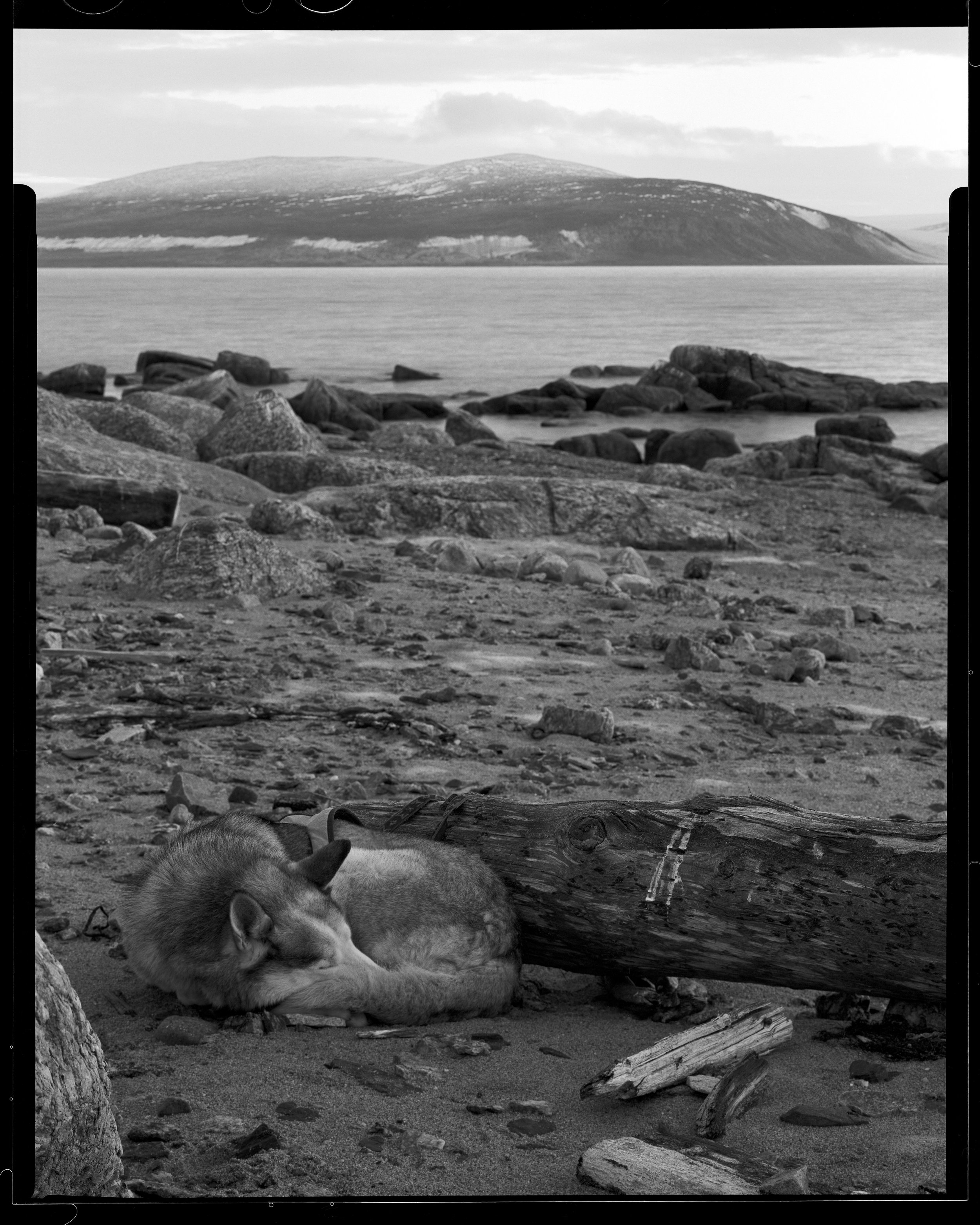

A very important member of our expedition crew was Hildago (not Hidalgo). He belonged to Piotr, one of our guides.

Hildago joined us on the zodiac for most landings and helped keep an eye out for polar bears. But once he was satisfied, he would find a good spot to curl up for a couple winks.

On the ship, he wasn’t allowed in the galley but he tried occasionally. Always made me feel bad when he got expelled. But he wasn’t ever left wanting for attention. He’s a handsome, mild-mannered guy with a brown eye and a blue eye and had a beautiful singing (howling) voice.

At age 8, Hildago is retired but spends his typical free days working at Huskies Cafe in Longyearbyen.

This sheet film was developed onboard our tall ship as we sailed.

Several walruses of a larger colony lie resting in a group on a snowy beach at Smeerenburg on Amsterdamøya (Amsterdam Island). The mountainous coastline of Spitsbergen is visible in the distance.

We took our time approaching this colony of about fifty. They knew we were there. We raised some initial curiosity but kept our distance and they did not mind our presence. The photograph suggests a more placid scene than it was. They were noisy, restless bedfellows perpetually complaining and poking at one another. Some left their group to try another. A handful of animals hauled in or hauled back out to sea while others bathed in the shallows. We were generally upwind but occasionally it would shift and we got a nostril full of something between cow pasture and low tide.

This day was incredible. It was a joy to see these animals thriving in their natural habitat. We spent nearly an hour watching and, although I shot all dozen of my sheets of film, it was tough to pack up and hike back down the coast to our zodiac, straining to hear their grunts and groans as they faded away into the silence.

Three centuries of commercial hunting brought Svalbard walruses nearly to extinction. In 1952, a hunting ban was passed to protect the hundred or so walrus remaining. Today, the population has rebounded and approximately six thousand live in the archipelago. Terrestrial haul-out sites like the broad, shallow beaches at Smeerenburg are vital to walruses, especially as populations rebound and pack ice retreats and shrinks.

Our lovely barquentine, Antigua, off Prins Karls Forland with Spitsbergen behind. This was toward the end of our voyage. I had had a frustrating morning at our landing. The wind was strong and nearly took my camera several times. Each time I set up a shot, the light would go flat before I could snap the shutter. While returning to the ship, I said, “There’s the shot,” but it was too late. Our zodiac was leaving.

There would be no opportunity for project work in the afternoon—a hike was planned.

At lunch, I lamented over the shot not taken. Then, an idea! I proposed to our guide Sergei to let me go on the first zodiac. I’d jump out, set up the shot, and break everything down before the second zodiac was ready to return to the ship. Sergei was skeptical, “You’d have to be quick…”

When the time came, I jumped in first and sat at the bow. Everyone else piled in and away we went. I was the first out at shore.

Now, a large format camera is not easy to assemble but I knew my gear. I got it mounted to the tripod, added rail extensions, leveled it, and got the ship in focus, metered the shot, placed my zones, and set the aperture and shutter. I shot four sheets.

The second zodiac was taking off from the ship. (It’s in my last two frames.) Then I broke that camera down as quick as could be and got everything back in its spot in the case. (The box wouldn’t close if everything wasn’t just so.) The base wouldn’t unscrew from the tripod—and the second zodiac was here unloading people! Finally it came apart! I closed the case and ran over.

A large format land speed record: I was on shore less than 6 minutes!

Sergei gave me a nod and a grin. Estée was piloting the zodiac and looked amused. As we pulled away she asked, “So…do you want to go back normal speed or fast?” “I’m happy to go fast.” She gunned it and we sped across the chop, spray flying, but we were too fast for it to come aboard.

This film was developed onboard our ship.

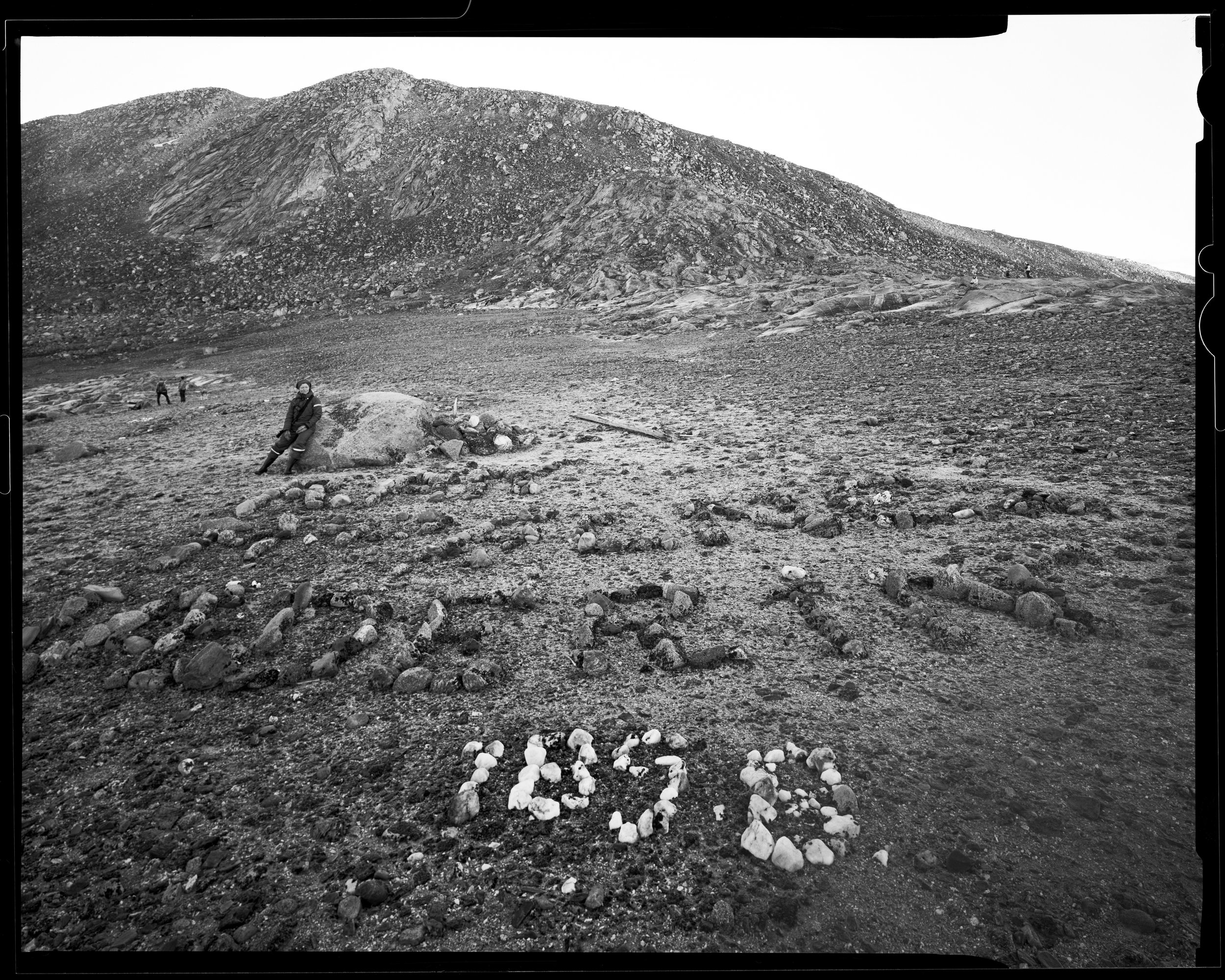

Stones arranged on a beach spell out the name of the Jäderin Expedition that landed here in 1898.

Our expedition leader, Sarah, leans against a large boulder at the top of the marker. Rocks piled against the other end of the boulder look similar to a whaler’s grave but we suspect they once held up the wooden pole now lying on the ground. The marker is difficult to see from a distance and a flag would have been helpful to future visitors looking for the landing site.

We began our voyage without a set itinerary; our tall ship would sail where the winds took us. Departing Longyearbyen, we had no concept of the possibility, much less any right to expect, that four days later we would have crossed north of the 80th parallel and breezed past Moffen Island to stand on the north coast of Nordaustlandet. But that is precisely what happened, and upon finding ourselves in this loneliest of places, Sarah recalled a story about Swedish explorer Edvard Jäderin.

In the late 1800s, the Swedish and Russian governments planned a joint scientific expedition called “Arc-of-Meridian” which would take place between 1899 and 1902. The goal was to make triangulated measurements, north to south, across Svalbard to determine whether the earth was spherical or if its curvature flattened near the pole as predicted by Newton. Russians were responsible for the south and the Swedes for the north. In 1898, Edvard Jäderin led a preparatory expedition to scout Nordaustlandet.

There was rumored to be a beach where Jäderin’s crew landed and laid out stones spelling their name and date. While there were some vague clues to its location, neither Sarah nor our other crew had ever seen it. Until now. Hands down, one of the greatest days on our voyage was discovering these stones laid down 125 years earlier and left undisturbed ever since.

Nearby is a similar marker from 1928 written in Russian that was made by the crew of the Soviet icebreaker Krassin (Red Bear). Krassin participated in the rescue of Umberto Nobile’s crew of the crashed dirigible Italia. In between is an arrangement of stones in the shape of a swastika believed to have been made around 1941 by the crew of a Nazi submarine transporting personnel to a nearby weather station.

This sheet film was developed onboard our tall ship as we sailed.

Next to Jäderin’s expedition marker (previous post) was a similar stone marker left in 1928 by the Soviet icebreaker Красный Медведь (Krassin, Red Bear). This ship participated in a multinational rescue effort following the crash of Umberto Nobilé’s airship Italia.

The rescue attempt is a bigger comedy of errors than the airship crash. Famous explorer Roald Amundsen’s plane disappeared on his way from Oslo to Spitsbergen to join the search. It takes 48 days to rescue all the survivors and stranded rescuers.

This sheet film was developed onboard our tall ship as we sailed.

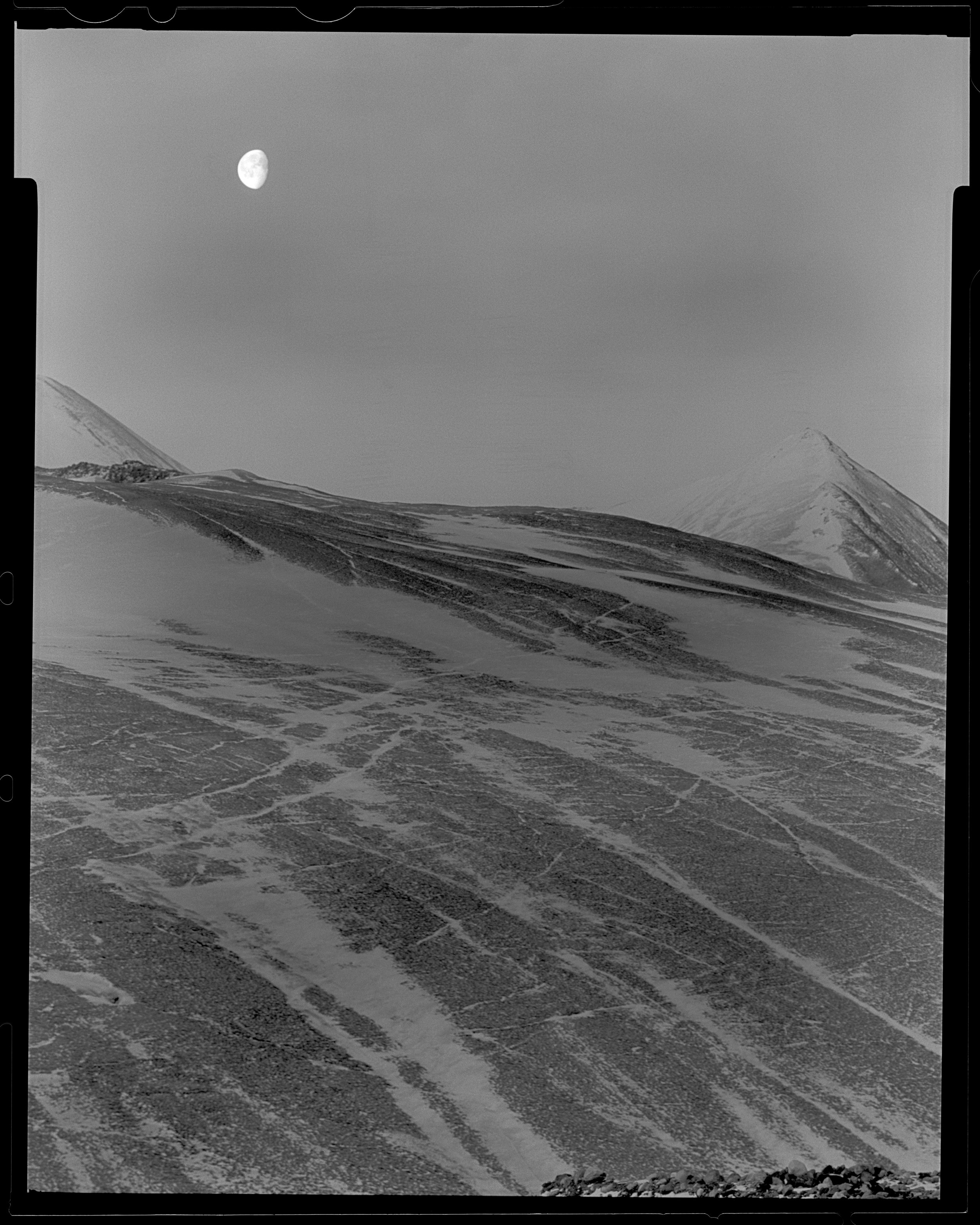

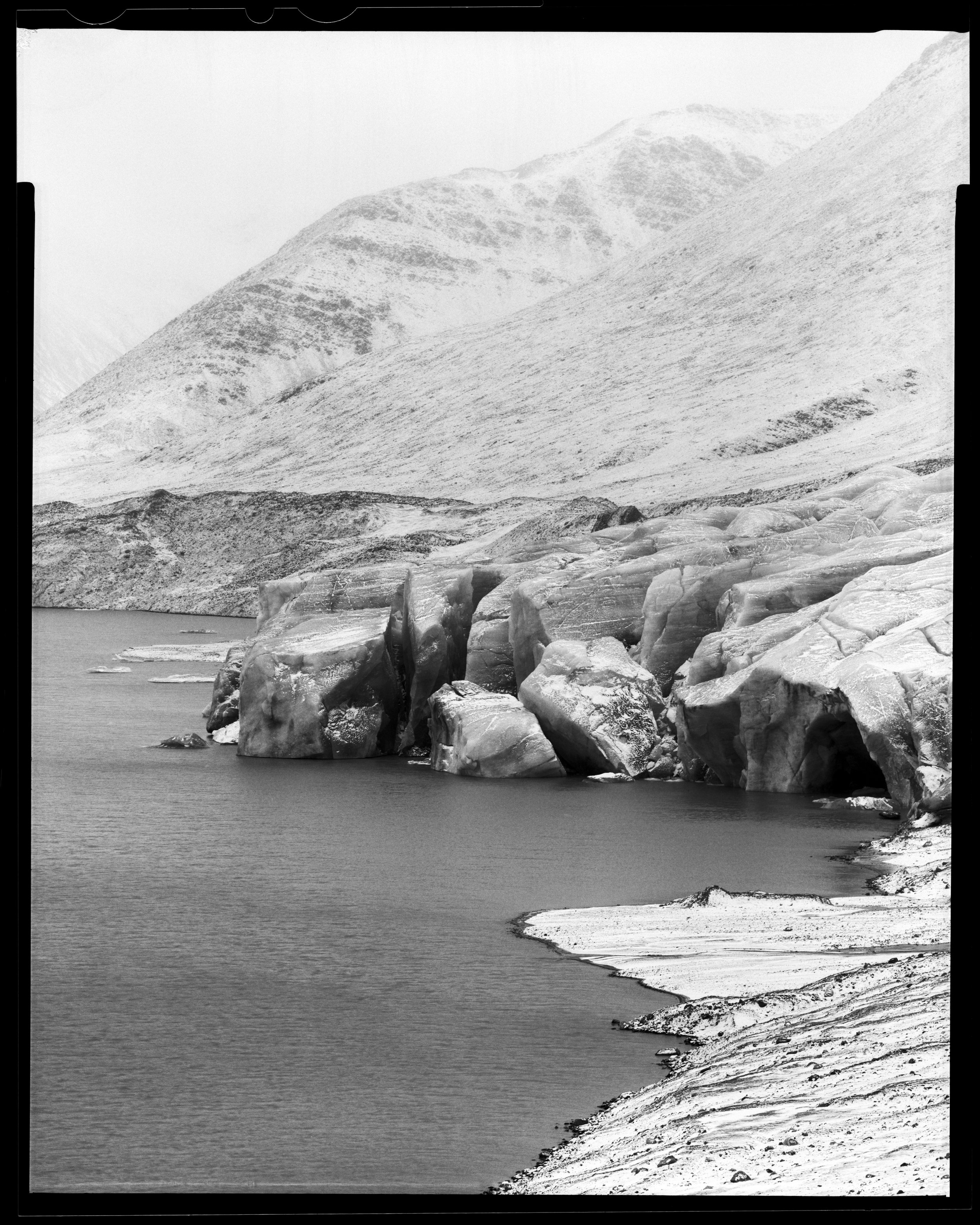

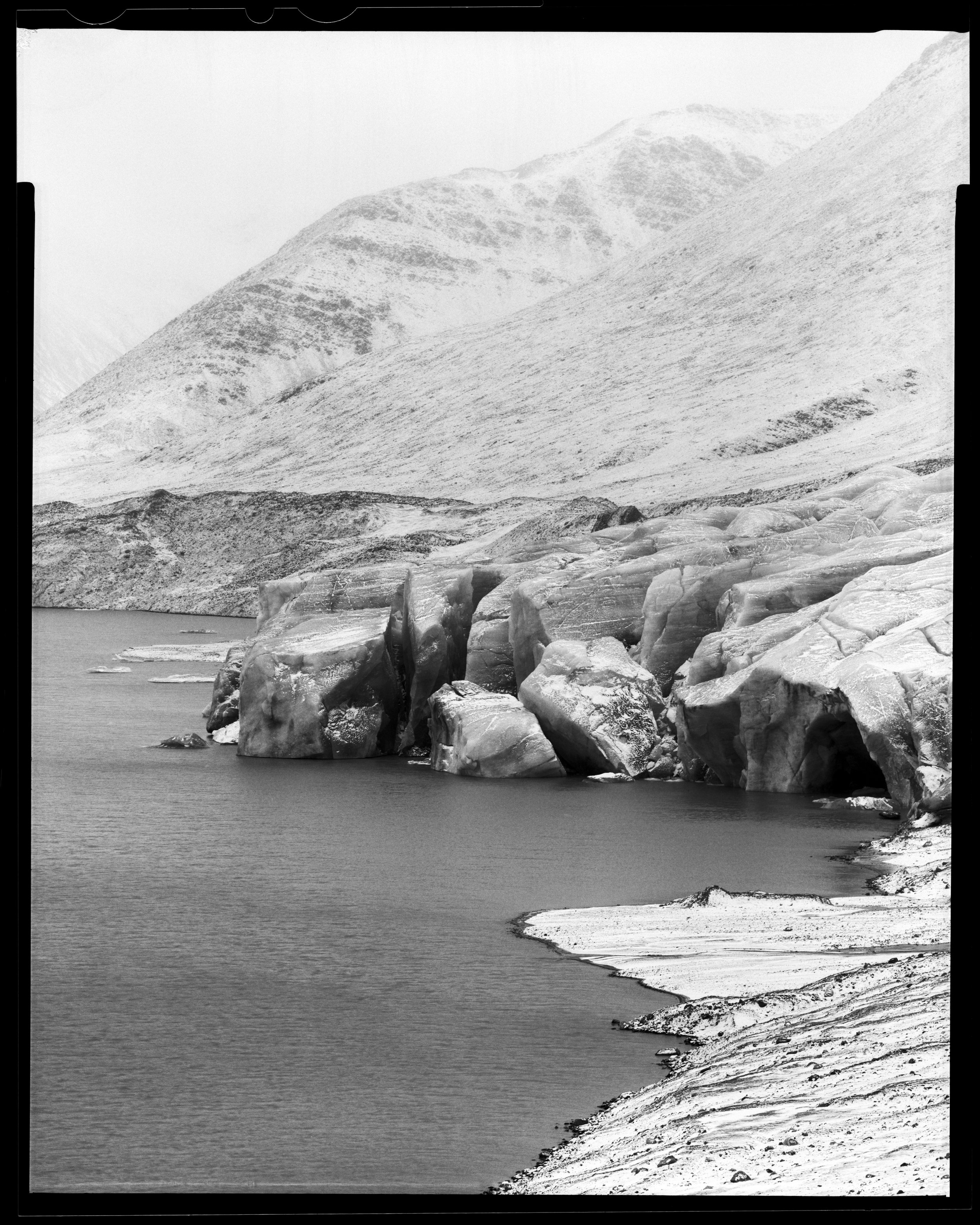

Over the ridge from the previous post at Hornbækpollen was this view down to Erikbreen Glacier and its massive freshwater lake. Sediment colored the water darker and browner than the sea looking back. Fresh snow from the evening before gave texture to the landscape.

It was a very windy day that more than once threatened to sweep my camera from the heights but I found some shelter in a nook in the rocks.

Glaciers make grinding, crashing, even thundering sounds. And you never know exactly where it’s coming from. This glacier was was actively making noise but only once did we see the falling ice that produced it.

Svalbard, very close to the North Pole, is warming six times faster than the rest of the world. This problem will accelerate as thawing permafrost releases methane, more than 20 times effective than carbon dioxide as a greenhouse gas. Dark surfaces absorb heat. Glacier shrinkage and loss of pack ice also reduces the earth’s capacity to reflect solar gain back out of the atmosphere.

This sheet film was developed aboard our tall ship as we sailed.

While visiting a historic miners’ cabin in Gipsdalen valley in Sassenfjorden, Spitsbergen, I captured this view of our ship, Antigua, at single anchor in Gipsvika Bay. It was mid-October and the stream cutting through the glacial moraine in the foreground was frozen solid. Svalbard has no trees and little soil and a dusting of new snow highlights the layers of ancient sedimentary rock forming its mountains.

This sheet film was developed onboard our tall ship as we sailed.

While visiting a historic miners’ cabin in Gipsdalen valley in Sassenfjorden, Spitsbergen, I captured this view of our ship, Antigua, at single anchor in Gipsvika Bay. It was mid-October and the stream cutting through the glacial moraine in the foreground was frozen solid. Svalbard has no trees and little soil and a dusting of new snow highlights the layers of ancient sedimentary rock forming its mountains.

This sheet film was developed onboard our tall ship as we sailed.

Captain of the tall ship Antigua, Jonathan, outside the wheelhouse. We sailed under wind power more on this voyage than the ship had on all others combined this season.

The Antigua is rigged as a barquentine, three masts with square sails on the foremast only, fore-and-aft rigged on the main and mizzen. It only takes a small crew to operate, although passengers like myself were welcomed to haul lines, set sheets, and furl sails with the crew.

I was making a portrait of the first mate, Matu, inside the wheelhouse. Jonathan was sitting back, watching us, making the occasional comment for Matu and smirking a bit. Then Matu had to leave to deal with something.

I was putting stuff away when Jonathan asked what it was all about. I said I thought it might be fun to get some photos of the people who brought us out here. I said I’d be happy to make a picture of him if he wanted. He said, “No, I don’t need to.”

To which I replied, “Yeah, no worries! I don’t need to bother everybody.”

“Well . . . I could do one.”

“Ok, sure. Let me set up something a little different. Maybe out here…?”

I made two shots in this absolutely beautiful light in front of the wheelhouse and they both turned out.

At the end of this season, Jonathan is giving up captaincy to head back to the Netherlands to be a kindergarten teacher (for which sailing a bunch of us around the dangers of the Arctic might well prepare him).

This sheet film was developed onboard our tall ship as we sailed.

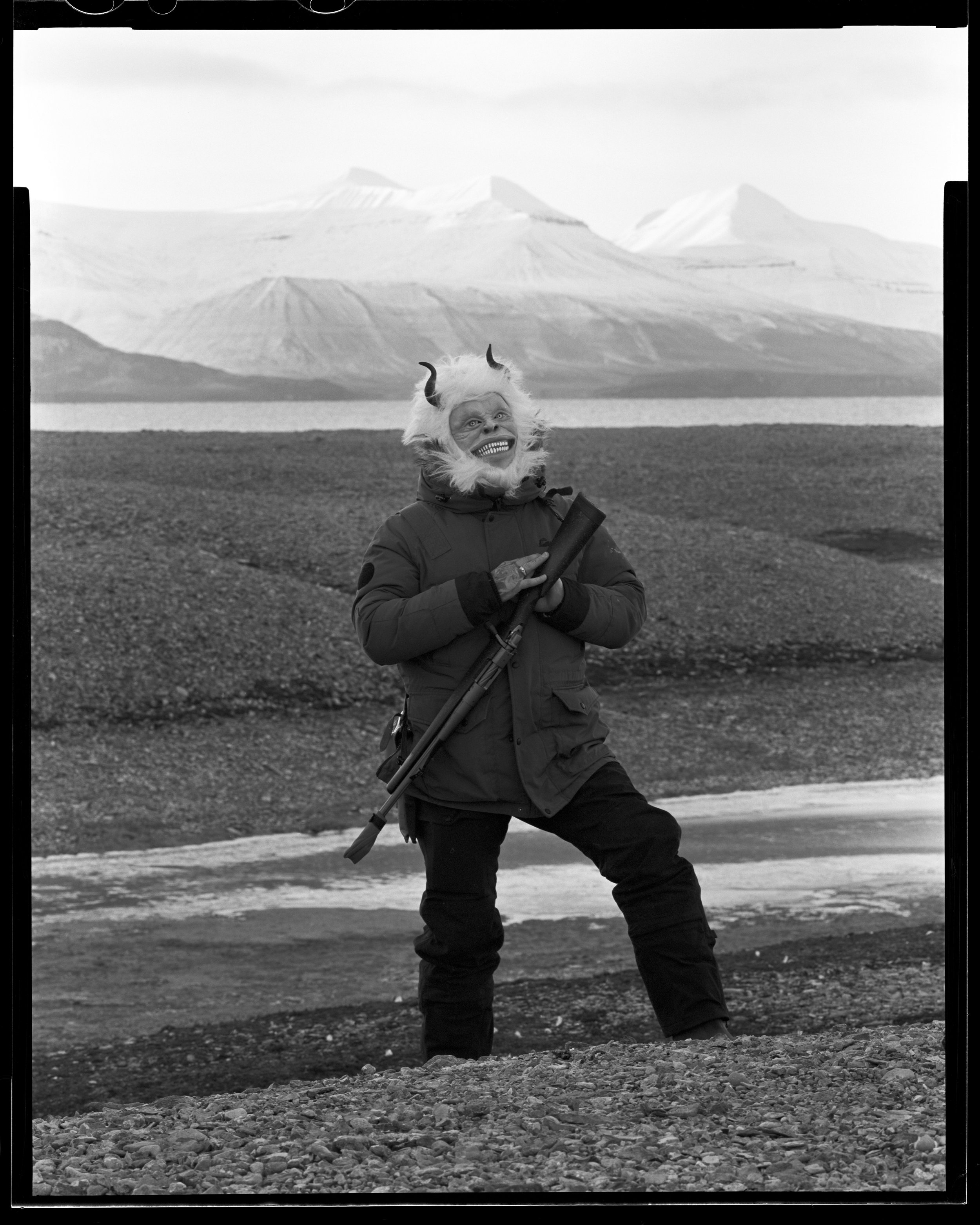

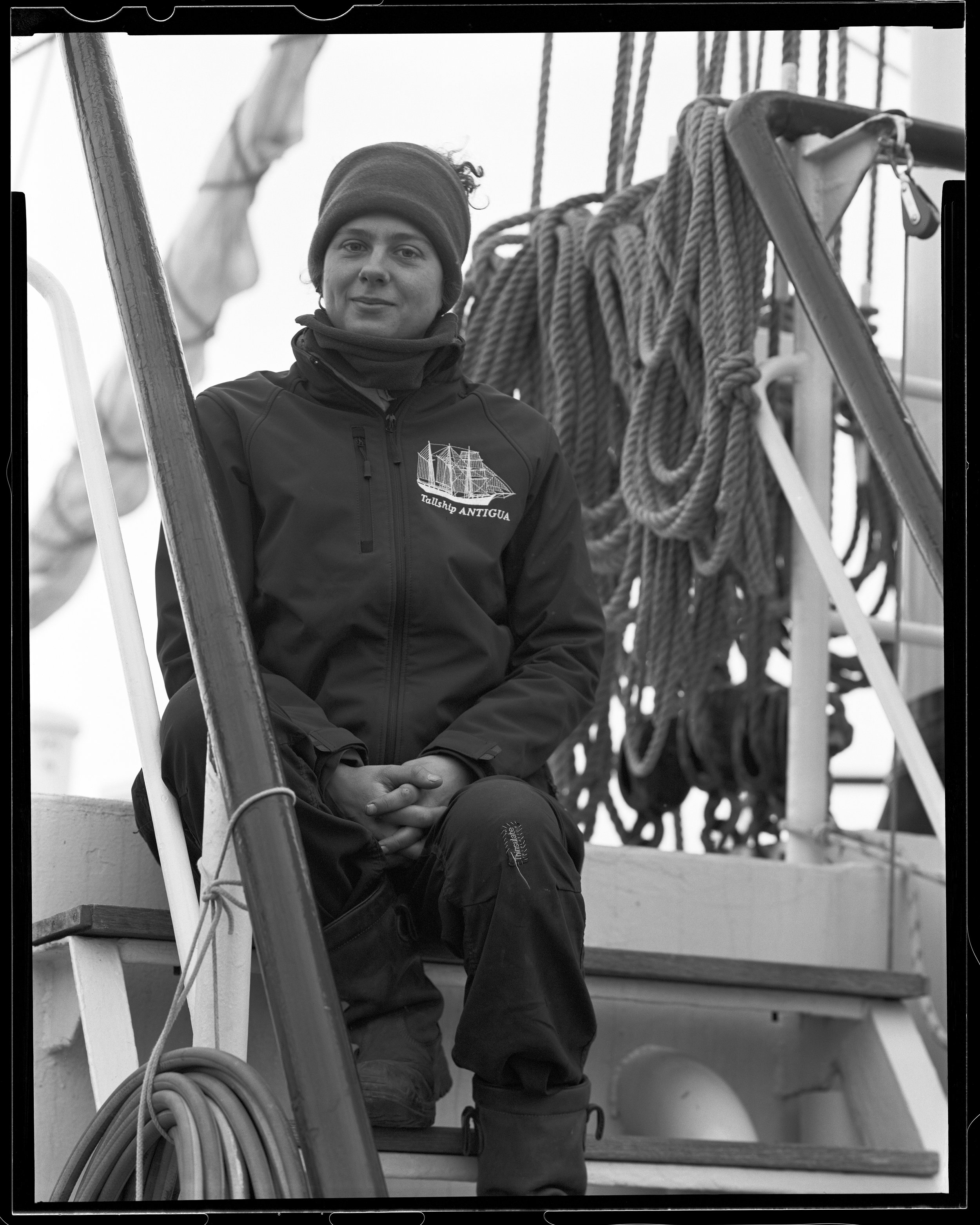

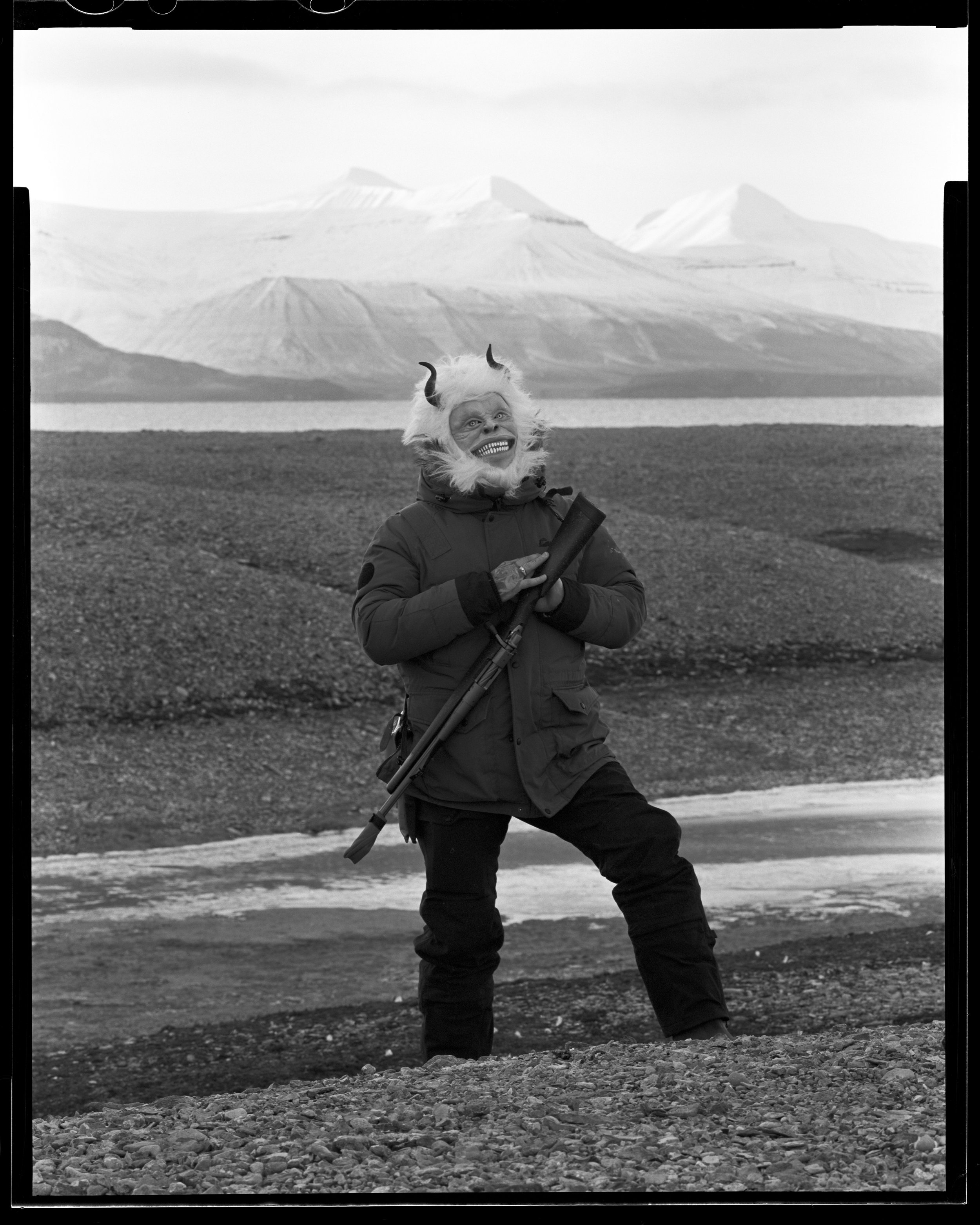

Our expedition manager and lead guide, Sarah. This was taken in Virgohamna on Danskøya, the launch site for Andrée’s ill-fated balloon attempt for the North Pole in 1897. The site is still littered with wood from structures and metal barrel hoops, all protected and untouchable. In fact, we couldn’t venture as far as we would like because a fresh dusting of snow made it impossible to know what we might be stepping on so we stayed strictly along the high water mark of the shore.

Note, Sarah’s rifle. It is illegal to be on land without rifles and flares (and training) as protection from polar bears. The goal is never to kill a bear except as a last resort. Both gun and flare are used to scare off a bear while humans find a way to retreat.

The guides would visit a landing first, then if everything was safe and land-able, the artists would come over about 8 or 10 at a time in a zodiac. The ship had three zodiacs but we typically only used the two larger ones. The guides would set up a perimeter in which we could work. They kept watch on the surroundings. Only twice did we ever see polar bears in the distance. Notice Sarah’s radio near her collar. The guides and the ship kept in close communication the whole time we were out.

Since we had such good winds, we sailed to far off places we had no right to expect to visit. Some of our crew and guides had seen a few of these sites before but we quickly got the sense that we were really exploring, not checking off a list, and our plans changed with the weather.

This sheet film was developed onboard our tall ship.

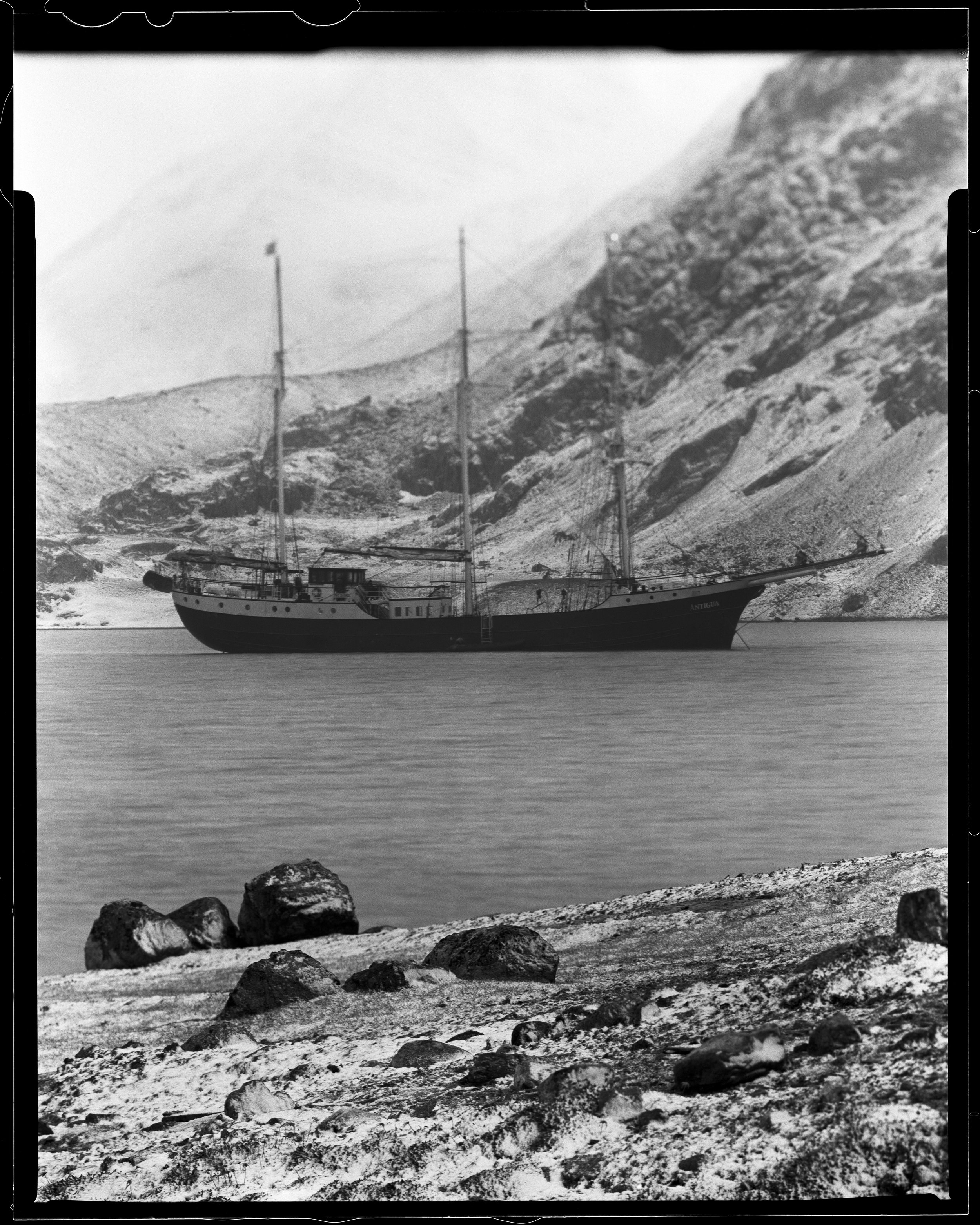

Sailing the Antigua into Hornbækpollen through a small break in the rocks that form this tiny bay was damned exhilarating! We were under wind power alone. I helped work the foremast square sails from the forepeak.

We had to furl sails to slow down but the wind in the rigging kept us moving at a couple knots. We slipped through a gap that was a biscuit toss to either side with little more than a meter or two under our keel. Once through, we had to work smartly lest we run aground. We brought the yards around, started our turn, dropped anchor, and, as we drifted over, came to the sweetest stop. Cheers and high fives all around!

Once all was ship shape, we dropped a zodiac and motored back to those rocks to catch the last light of the day. Clouds and fog rolled in and it began to snow.

The shot looks bright but I could hardly see the image on the ground glass. It was getting cold and my breath fogged the camera, my glasses, and the loupe. I used several degrees of tilt to put the plane of focus through the foreground, ship’s hull, and distant mountains. Because of the low light and the movement of the ship, I couldn’t stop down much. Those masts fall out of focus pretty quickly but I really like the final image.

The next day, we would climb that ridge in the background to see what was on the other side.

This sheet film was developed aboard our tall ship as we sailed.

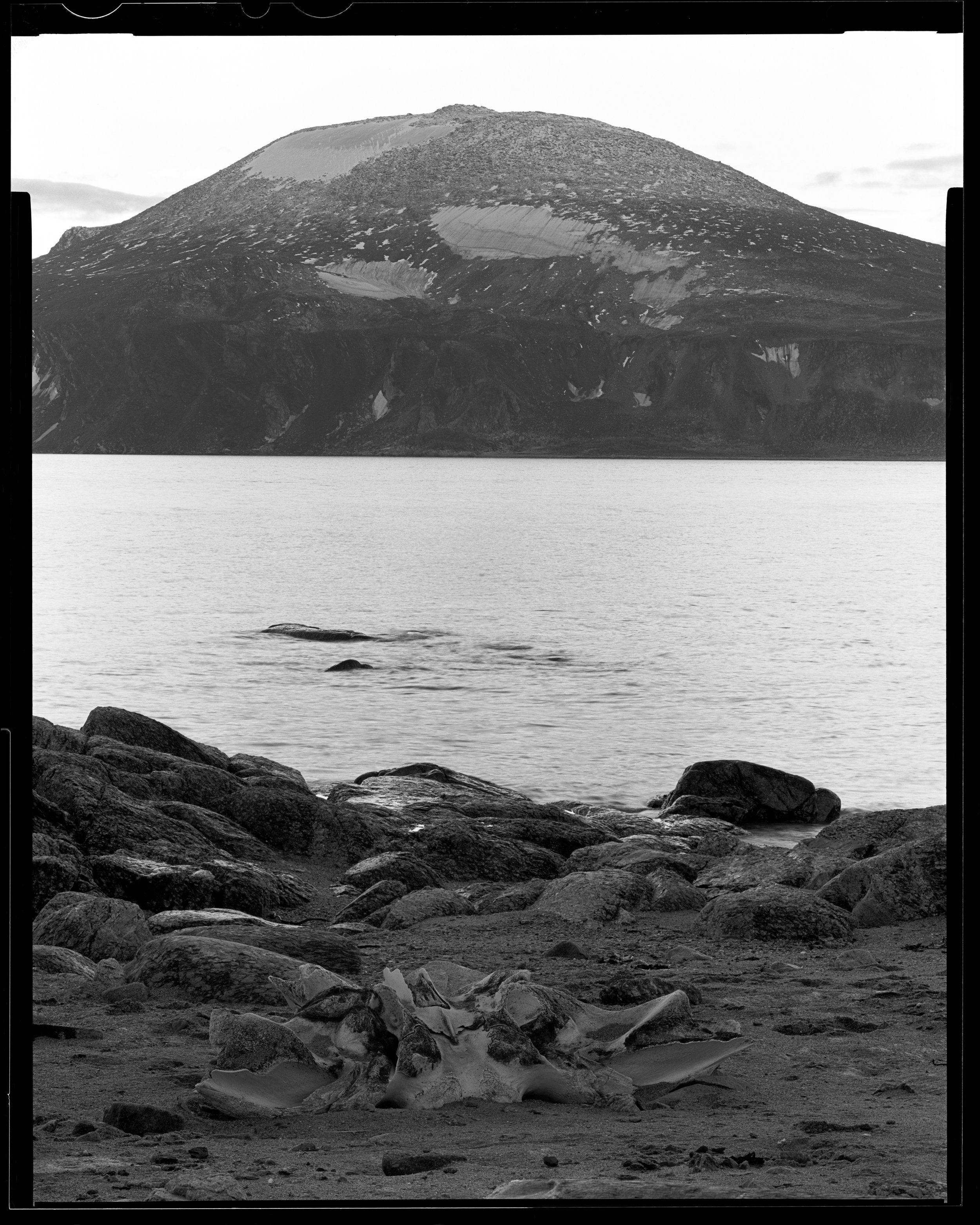

Here we were anchored at Sallyhamna in Fairhaven in the far northwest of Spitsbergen. We had tremendously favorable winds that swept us up the west coast overnight.

The cabin belonged to Waldermar and Sally Kraemer (after whom the harbor is named). It was built in 1937 over an older whaler’s blubber oven. Other blubber ovens dot the landscape to the right. Sally wintered-over here alone.

This was one of the few sites we visited with a healthy growth of moss and lichen. This is because century-old oils and blood from whales still provide enough organic nutrients to support their growth. These lichens are protected, as are the remnants of structures. People are not allowed to walk on them.

This sheet film was developed onboard our tall ship as we sailed.

Esmarkbreen was one of the few glaciers we could walk up to. This spectacularly twisted ice form leaned perilously over but, so far, has refused to succumb to gravity. The moraine I am standing on was covered by several stories worth of glacial ice a decade earlier.

Ymerbukta Bay was near the end of our time onboard. In Norse mythology, Ymer was the first being and father of giants. When he was slain, Odin used his body to create the earth, water, and sky.

To stand dwarfed at the foot of an ancient glacier is to experience those primordial beginnings of our world. Some glaciers are alive with grinding, crashing, even thundering noise and it can be difficult to tell exactly where the sound is coming from. Some calve dramatically into the sea. Esmarkbreen was quieter than others and invited us to come close, which made it all the more impressive.

We had several hours to work on the moraine on this particularly cold afternoon. Days were getting shorter by nearly twenty minutes per day and the moon was up pretty much all hours. As we worked, the sky dimmed, the moon got brighter, and cold air washed down on us from above.

Despite the chill in the air, Svalbard is warming six times faster than the rest of the world. This problem will accelerate as thawing permafrost releases methane, over twenty times more effective than carbon dioxide as a greenhouse gas. Dark surfaces like the moraine absorb heat. Glacier shrinkage and loss of pack ice also reduces the earth’s capacity to reflect solar gain back out of the atmosphere.

The ice in this photo is thousands, if not tens of thousands, of years old. In the past hundred years, Esmarkbreen has retreated five kilometers or about a quarter of its length. How long does Esmarkbreen have before it succumbs entirely?

Some days the light was so strange and wonderful. Every day had about twenty minutes less daylight than the one before it. Sometimes the sun and the moon would hang above opposite sides of the horizon.

This moonrise was toward the end of our trip at Esmarkbreen Glacier. As light quickly faded in the afternoon, the full moon grew more distinct.

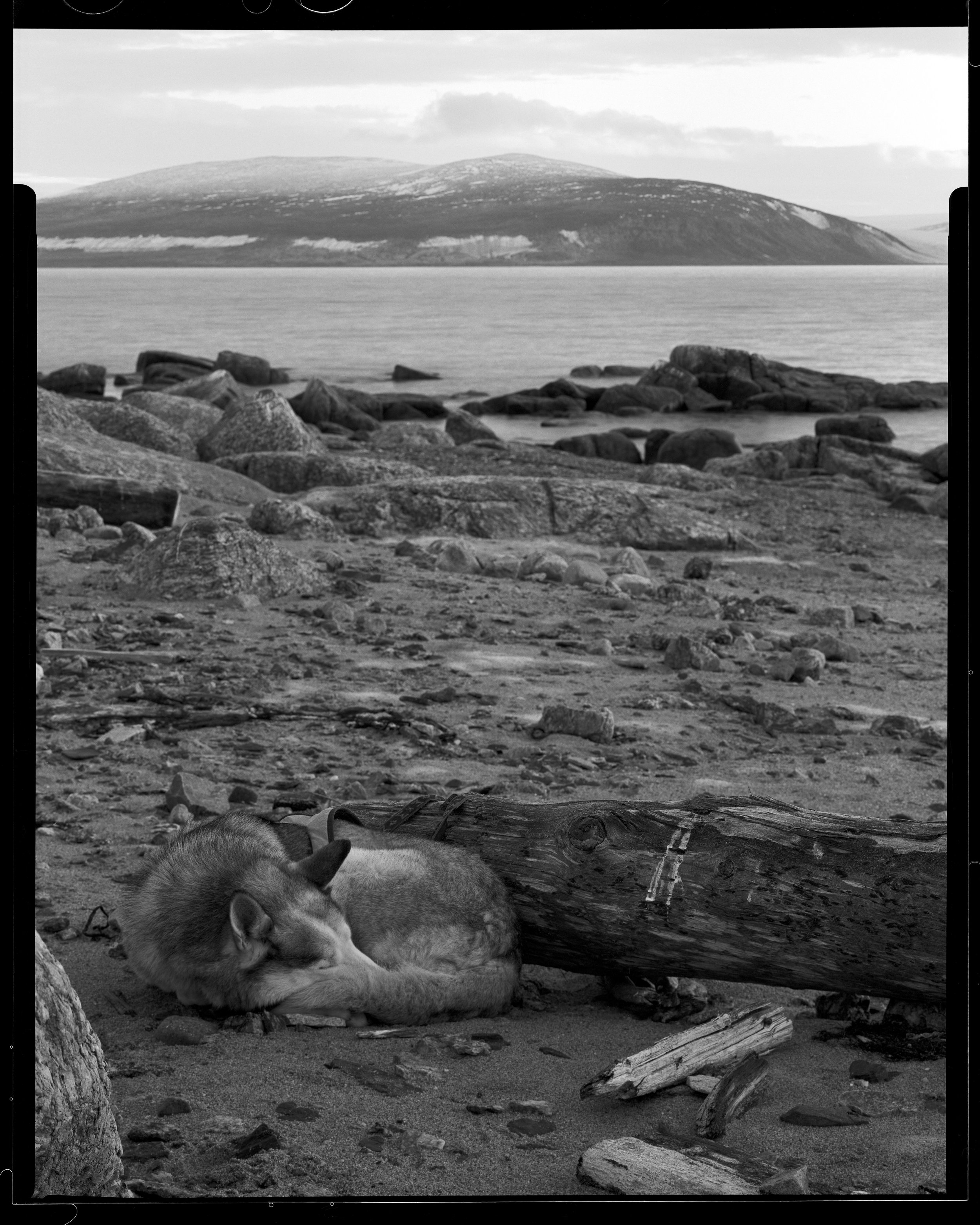

A very important member of our expedition crew was Hildago (not Hidalgo). He belonged to Piotr, one of our guides.

Hildago joined us on the zodiac for most landings and helped keep an eye out for polar bears. But once he was satisfied, he would find a good spot to curl up for a couple winks.

On the ship, he wasn’t allowed in the galley but he tried occasionally. Always made me feel bad when he got expelled. But he wasn’t ever left wanting for attention. He’s a handsome, mild-mannered guy with a brown eye and a blue eye and had a beautiful singing (howling) voice.

At age 8, Hildago is retired but spends his typical free days working at Huskies Cafe in Longyearbyen.

This sheet film was developed onboard our tall ship as we sailed.

Several walruses of a larger colony lie resting in a group on a snowy beach at Smeerenburg on Amsterdamøya (Amsterdam Island). The mountainous coastline of Spitsbergen is visible in the distance.

We took our time approaching this colony of about fifty. They knew we were there. We raised some initial curiosity but kept our distance and they did not mind our presence. The photograph suggests a more placid scene than it was. They were noisy, restless bedfellows perpetually complaining and poking at one another. Some left their group to try another. A handful of animals hauled in or hauled back out to sea while others bathed in the shallows. We were generally upwind but occasionally it would shift and we got a nostril full of something between cow pasture and low tide.

This day was incredible. It was a joy to see these animals thriving in their natural habitat. We spent nearly an hour watching and, although I shot all dozen of my sheets of film, it was tough to pack up and hike back down the coast to our zodiac, straining to hear their grunts and groans as they faded away into the silence.

Three centuries of commercial hunting brought Svalbard walruses nearly to extinction. In 1952, a hunting ban was passed to protect the hundred or so walrus remaining. Today, the population has rebounded and approximately six thousand live in the archipelago. Terrestrial haul-out sites like the broad, shallow beaches at Smeerenburg are vital to walruses, especially as populations rebound and pack ice retreats and shrinks.

Our lovely barquentine, Antigua, off Prins Karls Forland with Spitsbergen behind. This was toward the end of our voyage. I had had a frustrating morning at our landing. The wind was strong and nearly took my camera several times. Each time I set up a shot, the light would go flat before I could snap the shutter. While returning to the ship, I said, “There’s the shot,” but it was too late. Our zodiac was leaving.

There would be no opportunity for project work in the afternoon—a hike was planned.

At lunch, I lamented over the shot not taken. Then, an idea! I proposed to our guide Sergei to let me go on the first zodiac. I’d jump out, set up the shot, and break everything down before the second zodiac was ready to return to the ship. Sergei was skeptical, “You’d have to be quick…”

When the time came, I jumped in first and sat at the bow. Everyone else piled in and away we went. I was the first out at shore.

Now, a large format camera is not easy to assemble but I knew my gear. I got it mounted to the tripod, added rail extensions, leveled it, and got the ship in focus, metered the shot, placed my zones, and set the aperture and shutter. I shot four sheets.

The second zodiac was taking off from the ship. (It’s in my last two frames.) Then I broke that camera down as quick as could be and got everything back in its spot in the case. (The box wouldn’t close if everything wasn’t just so.) The base wouldn’t unscrew from the tripod—and the second zodiac was here unloading people! Finally it came apart! I closed the case and ran over.

A large format land speed record: I was on shore less than 6 minutes!

Sergei gave me a nod and a grin. Estée was piloting the zodiac and looked amused. As we pulled away she asked, “So…do you want to go back normal speed or fast?” “I’m happy to go fast.” She gunned it and we sped across the chop, spray flying, but we were too fast for it to come aboard.

This film was developed onboard our ship.

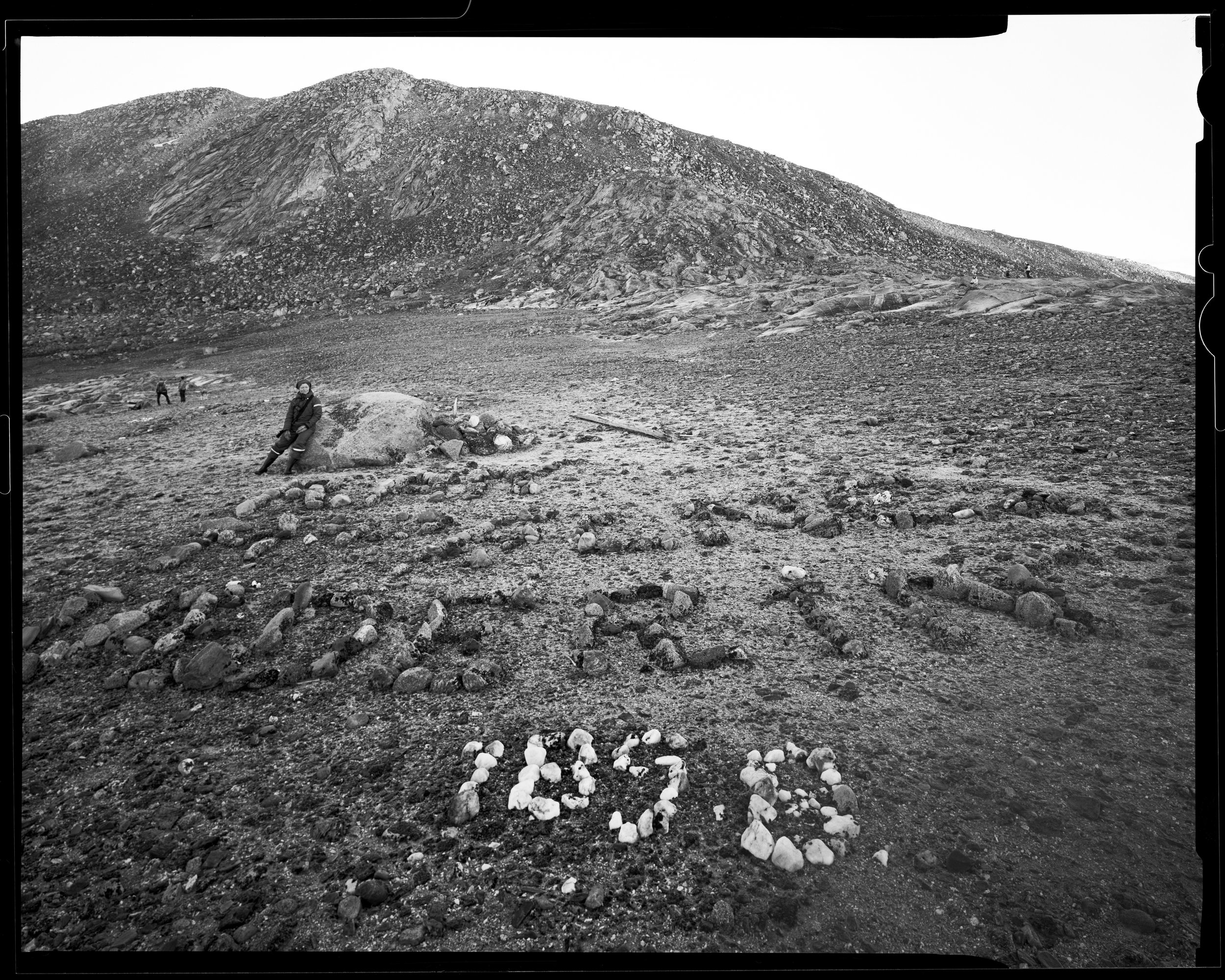

Stones arranged on a beach spell out the name of the Jäderin Expedition that landed here in 1898.

Our expedition leader, Sarah, leans against a large boulder at the top of the marker. Rocks piled against the other end of the boulder look similar to a whaler’s grave but we suspect they once held up the wooden pole now lying on the ground. The marker is difficult to see from a distance and a flag would have been helpful to future visitors looking for the landing site.

We began our voyage without a set itinerary; our tall ship would sail where the winds took us. Departing Longyearbyen, we had no concept of the possibility, much less any right to expect, that four days later we would have crossed north of the 80th parallel and breezed past Moffen Island to stand on the north coast of Nordaustlandet. But that is precisely what happened, and upon finding ourselves in this loneliest of places, Sarah recalled a story about Swedish explorer Edvard Jäderin.

In the late 1800s, the Swedish and Russian governments planned a joint scientific expedition called “Arc-of-Meridian” which would take place between 1899 and 1902. The goal was to make triangulated measurements, north to south, across Svalbard to determine whether the earth was spherical or if its curvature flattened near the pole as predicted by Newton. Russians were responsible for the south and the Swedes for the north. In 1898, Edvard Jäderin led a preparatory expedition to scout Nordaustlandet.

There was rumored to be a beach where Jäderin’s crew landed and laid out stones spelling their name and date. While there were some vague clues to its location, neither Sarah nor our other crew had ever seen it. Until now. Hands down, one of the greatest days on our voyage was discovering these stones laid down 125 years earlier and left undisturbed ever since.

Nearby is a similar marker from 1928 written in Russian that was made by the crew of the Soviet icebreaker Krassin (Red Bear). Krassin participated in the rescue of Umberto Nobile’s crew of the crashed dirigible Italia. In between is an arrangement of stones in the shape of a swastika believed to have been made around 1941 by the crew of a Nazi submarine transporting personnel to a nearby weather station.

This sheet film was developed onboard our tall ship as we sailed.

Next to Jäderin’s expedition marker (previous post) was a similar stone marker left in 1928 by the Soviet icebreaker Красный Медведь (Krassin, Red Bear). This ship participated in a multinational rescue effort following the crash of Umberto Nobilé’s airship Italia.

The rescue attempt is a bigger comedy of errors than the airship crash. Famous explorer Roald Amundsen’s plane disappeared on his way from Oslo to Spitsbergen to join the search. It takes 48 days to rescue all the survivors and stranded rescuers.

This sheet film was developed onboard our tall ship as we sailed.

Over the ridge from the previous post at Hornbækpollen was this view down to Erikbreen Glacier and its massive freshwater lake. Sediment colored the water darker and browner than the sea looking back. Fresh snow from the evening before gave texture to the landscape.

It was a very windy day that more than once threatened to sweep my camera from the heights but I found some shelter in a nook in the rocks.

Glaciers make grinding, crashing, even thundering sounds. And you never know exactly where it’s coming from. This glacier was was actively making noise but only once did we see the falling ice that produced it.

Svalbard, very close to the North Pole, is warming six times faster than the rest of the world. This problem will accelerate as thawing permafrost releases methane, more than 20 times effective than carbon dioxide as a greenhouse gas. Dark surfaces absorb heat. Glacier shrinkage and loss of pack ice also reduces the earth’s capacity to reflect solar gain back out of the atmosphere.

This sheet film was developed aboard our tall ship as we sailed.